Tus nqi zoo tshaj plaws rau Tuam Tshoj Kub Phaj Vuam Tshuab yog tsim rau vuam dej qhov hluav taws xob ntsaws ntawm lub tshuab ntxhua khaub ncaws

Cov neeg siv khoom txaus siab yog peb lub hom phiaj tseem ceeb rau. Peb txhawb nqa ib qib zoo ib yam ntawm kev tshaj lij, zoo tshaj plaws, kev ntseeg siab thiab kho kom zoo tshaj tus nqi rauTuam Tshoj Kub Phaj Vuam TshuabTsim nyog rau Vuam Dej qhov hluav taws xob ntsaws ntawm lub tshuab ntxhua khaub ncaws, Ntau lub sijhawm, tam sim no peb tau them nyiaj rau txhua yam tshwj xeeb kom lav txhua yam khoom lossis kev pabcuam txaus siab los ntawm peb cov neeg yuav khoom.

Cov neeg siv khoom txaus siab yog peb lub hom phiaj tseem ceeb rau. Peb txhawb nqa ib qib kev ua haujlwm zoo ib yam, zoo tshaj plaws, kev ntseeg siab thiab kho rauTuam Tshoj Kub Phaj Vuam Tshuab, HDPE Kub Phaj Butt Vuam Tshuab, Tam sim no peb lub network muag khoom tau loj hlob tsis tu ncua, txhim kho kev pabcuam zoo kom tau raws li cov neeg siv khoom xav tau. Yog tias koj txaus siab rau txhua yam khoom, nco ntsoov tiv tauj peb txhua lub sijhawm. Peb tab tom nrhiav rau pem hauv ntej los tsim kev lag luam kev sib raug zoo nrog koj nyob ze yav tom ntej.

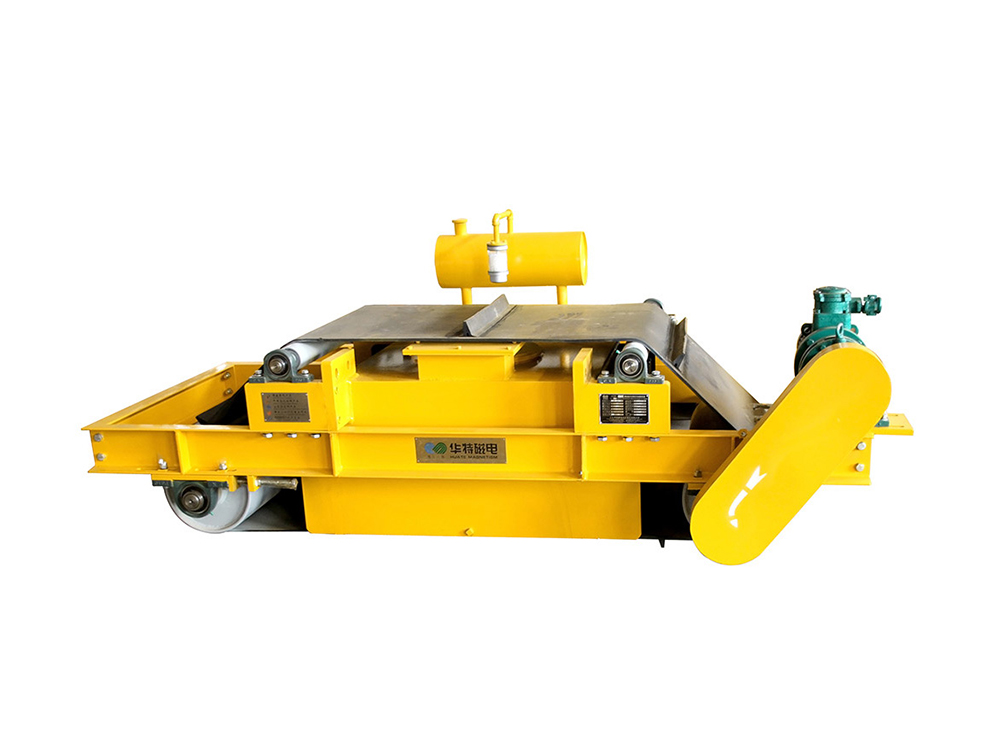

Technical specifications

◆ Kho lub computer simulation tsim, cov khoom no muaj cov yam ntxwv ntawm cov cim sib nqus Circuit Court, siab sib nqus siv thiab loj sib nqus nqus qhov tob.

◆ Kho cov khoom siv hluav taws xob ntshiab hlau nrog cov permeability siab thiab siab saturation sib nqus induction siv, txo cov hysteresis poob, thiab txhim kho kev ruaj ntseg ntawm cov hlau nplaum.

◆ Kev siv cov varnished insulating thiab curing processing technology, kev tiv thaiv lub kauj yuav tsis cuam tshuam los ntawm cov plua plav yaig, lub kauj muaj cov khoom siv rwb thaiv tsev zoo.

◆ Nrog zoo rotating thiab tsis zoo rotating hloov, qhov ceev thiab sij hawm yuav arbitrary hloov nyob rau hauv ib tug high degree ntawm automation.

◆ Kho qhov tshwj xeeb cua duct tsim thiab yuam cua txias, coil cua sov tso tawm sai thiab nrog kub tsis tshua muaj siab.

◆ Tus nqi ua haujlwm qis, siv hluav taws xob tsawg, txuag hluav taws xob thiab kev tiv thaiv ib puag ncig.

◆ Cov tshuaj nplawm kev siv zog tuaj yeem hloov kho tau yooj yim, cov nyhuv eddy tam sim no zoo, nplawm qhov tob thiab qhov loj.

◆ Nws yog txawm peem rau nrog advanced tej thaj chaw deb tswj system, automation degree yog siab, nws muaj phau ntawv thiab tsis siv neeg muaj nuj nqi, lub lag luam yog yooj yim thiab yooj yim.

Technical specifications

Muaj ntau lub qhov cua qhov nruab nrab ntawm qhov induction kauj ntawm DC electromagnetic stirrer kom dhau cua txias, ntawm ob sab ntawm lub kauj yog muab nrog ib tug cua qhia npog, adapting ob coils cua inlet symmetrical txias qauv, lub kauj tempera-ture nce yog tsawg thiab magnetic teb attenuation yog me me, ntxiv rau qhov tob tob tob ntawm lub cub tawg thiab aluminium tov.

Rotating hollow ncej yog muab rau ntawm lub sib nqus yoke ntawm ob lub kauj, muaj ntau cov cua vents nyob rau sab saum toj ntawm hollow ncej, sab nraud tau tsau cua qhia nplhaib, cua txias mus los ntawm cua qhia nplhaib thiab cua vents mus rau hauv lub coil, lub cua txias kuj yog me me thiab tso cua sov yog ceev.

DC coil txais cov txheej txheem ob txheej disc winding & 180 ℃ kub resistant thiab curing txheej txheem, lub kauj muaj kev hloov kho muaj peev xwm, ruaj khov & txhim khu kev lag luam thiab kev nyab xeeb siab.

Siv lub nplhaib conductive ua haujlwm siab, cov khoom siv ua haujlwm ruaj khov thiab txhim khu kev qha thiab muaj lub neej ua haujlwm ntev.