JCTN Raising Concentrate Qib thiab txo qis Dregs Cov ntsiab lus nruas

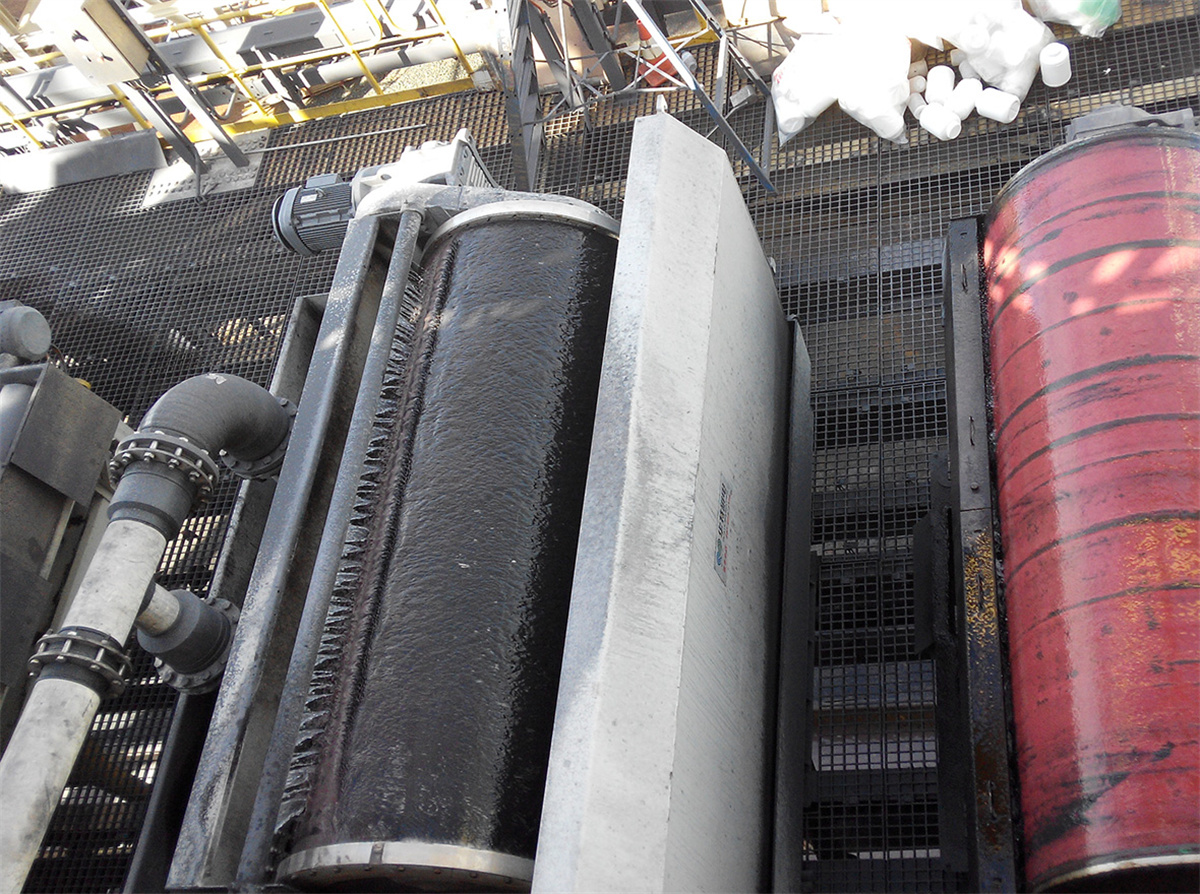

Permanent Sib Nqus Separator

JCTN Raising Concentrate Qib thiab txo qis Dregs Cov ntsiab lus Nruas PermanentMagnetic Separator tsim los ntawm peb lub tuam txhab. Nws txais yuav lub kaum sab xis loj ntawm 240 ° ~ 270 °, ntau tus ncej thiab cov qauv sib nqus sib nqus ua ke nrog ntau cov dej yaug dej, cov twj tso kua mis sab saum toj thiab lub tank tshiab, tuaj yeem nce qib siab los ntawm 2 ~ 10% piv nrog cov pa. magnetic separators tsis txo tus nqi rov qab, yog li daws qhov teeb meem uas cov pa sib nqus sib nqus sib nqus yog qhov nyuaj los txhim kho cov qib siab concentration tshwm sim los ntawm kev sib nqus agglomeration ntawm impurities.

Cov khoom tau thov rau domestic invention patents thiab thoob ntiaj teb invention patents, thiab dhau lub xeev thiab Ministerial khoom appraisal rau lub Tsib Hlis 30, 2015, uas yog thawj nyob rau hauv tsev thiab txawv teb chaws thiab thoob ntiaj teb ua theem.

Daim ntawv thov:

Cov khoom no yog cov khoom sib nqus ntub dej uas tsim los rau kev yaug thiab ua kom huv ntawm cov hlau nplaum sib nqus. Raws li cov txheej txheem yuav tsum tau, cov hlau nplaum hlau yog ntxuav, xaiv thiab purified, deslimed thiab concentrated. Muaj feem xyuam rau: sorting thiab desliming ntawm graded overflow cov khoom tom qab thawj sib tsoo; ntxhia concentration ua ntej kev sib tsoo thiab kev pom; desliming ntawm magnetite ua ntej nkag mus rau qhov zoo sieve tshuaj ntsuam thiab desliming ua ntej rov qab flotation; Nws yog qhov kawg xaiv ntawm magnetite.

JCTN txoj cai ua haujlwm

Tom qab cov ore slurry yog pub rau hauv lub raj pub khoom noj 1, nws tau ncaj qha pub rau hauv cov cuab yeej sorting cheeb tsam los ntawm qhov sib txawv ntawm daim ntaub. Cov hlau nplaum sib nqus hauv nws yog thawj zaug hlau nplaum thiab chained thiab txheej, thiab tom qab ntawd ncaj qha adsorbed rau ntawm lub nruas 3 los ntawm kev ua haujlwm zoo sib nqus, thiab cov hlau nplaum sib nqus tau tawm ntawm cov kua dej los ntawm lub nruas tig 3 , thiab magnetic concentrate yog thauj mus rau saum. Kev sib cais ntawm cov dej thiab ore tuaj yeem pom tau hauv cov txheej txheem ntawm kev xa khoom, thiab cov concentration tuaj yeem nce ntxiv. Nyob rau tib lub sij hawm, tom qab lub concentrate yog cais los ntawm cov kua nto, nws yog cuam tshuam los ntawm lub built-in stirring magnetic teb ntawm lub nruas 3 kom paub txog cov neeg kho tshuab txav ntawm rov agglomeration, dispersion, thiab agglomeration ntawm ore hais. , thiab nyob rau hauv lub rinsing ntawm multi-theem rinsing dej 2, impurities xws li silicon, sulfur, phosphorus thiab tsis zoo aggregate nyob rau hauv lub concentrate yuav zoo shaved, thiaj li hais tias cov qib ntawm cov concentrate tuaj yeem txhim kho ntau li ntau tau. Thaum kawg, ob txheej txheej scraper (Tshem tawm ntaus ntawv 4 thiab scraper 5), nws yog enriched rau hauv lub thawv concentrate 6 los ua concentrate; thiab cov hlau tsis muaj hlau nplaum thiab cov kab mob ntshiv, ua ke nrog cov ore ntws, nkag mus rau hauv lub qhov hluav taws xob 7 nyob rau hauv qab ntawm lub tank sorting los ua tailings los yog middlings.

Patent innovation ntsiab lus

1.Multi-stage yaug dej ntaus ntawv

Lub tank lub cev yog txawm peem rau nrog multi-channel rinsing pab kiag li lawm, uas siv tshwj xeeb cov txheej txheem stainless hlau nozzles kom huv si yaug cov zaub mov nyob rau ntawm lub nruas, kom impurities xws li silicon, sulfur, phosphorus thiab tsis zoo aggregate nyob rau hauv lub concentrate yuav ua tau zoo. shaved, los txhim kho cov concentration qib ntau li ntau tau.

◆ Sab saum toj kab hlau rhuav cov qauv

Sab saum toj ntawm lub tank yog nruab nrog cov ntaub thaiv dej rinsing qauv, uas tuaj yeem coj tau zoo silicon, sulfur, phosphorus thiab lwm yam impurities nyob rau hauv cov hlau nplaum agglomeration qhib nyob rau hauv qhov kev txiav txim ntawm ntau theem rinsing dej ntaus ntawv thiab cov sib nqus agitation ntaus ntawv thiab cov neeg pluag agglomeration. mus rau tailings, thiab tuaj yeem txo impurities rau hauv cov concentrate.

◆ Loj qhwv lub kaum ntse ntse multi-ncej magnetic system qauv

Cov txheej txheem sib nqus nrog 240 ° ~ 270 ° loj qhwv lub kaum ntse ntse thiab ntau qhov sib nqus ncej tuaj yeem ua rau cov pob zeb hauv av yob rau ntawm lub nruas ntau zaus, thiab tshem tawm cov silicon, sulfur, phosphorus, thiab lwm yam. qib ntawm cov concentrate.

◆ Sib nqus pulsation magnetic circuit technology

Muaj cov khoom sib nqus nplawm hauv lub nruas ntawm daim tawv nqaij, kom cov zaub mov txuas rau ntawm lub nruas tuaj yeem ua tau zoo sib nqus sib nqus, ua ke nrog ntau tus ncej hlau nplaum los tsim kom muaj lub zog sib nqus sib nqus, kom cov zaub mov tau rov ua dua. thiab sib cais, thiab yaug nrog dej yaug,

Nws tuaj yeem tshem tawm cov teeb meem tsis zoo xws li silicon, sulfur, phosphorus, thiab cov khoom tsis zoo hauv cov concentrate, yog li txhim kho qib ntawm cov concentrate.

◆ Kev tiv thaiv kabmob

Sab nrauv ntawm aluminium kawg npog siv lub qhov dav dav thiab cov qauv tsim nrog lub zais chamber sab hauv, uas tiv thaiv cov slurry los ntawm kev tsim tawm los ntawm kev nkag mus rau qhov sib koom ua ke ntawm cov ncej kawg thiab ntxiv dag zog rau kev sib khi ntawm cov khoom siv. Cov menyuam ncej kawg siv txoj kev sib txuas sib txuas ntawm ntau qhov zawj labyrinth txhua yam foob thiab lub ntsej muag foob lub nplhaib, uas tiv thaiv impurities los ntawm kev nkag mus rau qhov kawg thiab ua rau cov kabmob. Thiab muaj lub tes tsho ncej ntawm qhov kawg tsis tsav, uas tuaj yeem tiv thaiv kev puas tsuaj rau lub ncej thaum cov kabmob puas.

◆ Anhydrous ore unloading ntaus ntawv

Txais yuav ob lub scraper kom tawm cov ntxhia kom ua kom muaj qhov ceev ntawm cov khoom siv-resistuals.Qhov khoom siv uas muaj peev xwm ntev li cas lub neej.

◆ Dual filter flushing system

Lub tshuab ntxhua khaub ncaws tswj 8 cov kav dej los ntawm kev tswj valve.Cov yeeb nkab tseem ceeb muaj cov yeeb nkab lim thiab ob chav Y-zoo li cov yeeb nkab lim, uas tuaj yeem khaws lub nozzle los ntawm bloch rau kev ua haujlwm ntev.

◆ khoom noj khoom haus

Khoom noj khoom haus yog lub raj mis pub lub thawv, txuas los ntawm flange, uas txuas nrog 2-4 flanges, los ntawm cov khoom sib txawv ntawm cov khoom faib thiab cov khoom siv dhau. kom ua tiav lub hom phiaj ntawm kev faib khoom sib npaug. Lub 30mm thickness steel yeeb nkab nyob rau hauv qab kom ntseeg tau tias siv mus ntev yam tsis tau hnav tawm.

◆ Kev sib kis

JCTN magnetic separator yog nruab nrog lub zaus hloov pauv ceev tswj kev tswj cov cuab yeej, uas tuaj yeem kho qhov ceev ntawm cov khoom siv raws li cov khoom ntawm cov khoom siv hauv qhov chaw, thiaj li ua tiav cov khoom siv ntxhia sib xws.

◆ High concentrate lub thawv

Lub thawv concentrates tau txais cov qauv siab, uas tuaj yeem tiv thaiv cov slurry los ntawm kev sib tsoo tawm, thiab cov ntawv hnav-resistant ceramic yog muab tso rau ntawm qhov chaw uas yooj yim hnav kom ua rau lub neej kev pab cuam ntawm lub thawv concentrate.

Main technical parameters

| Qauv | Nruas Dimension (D × L) (mm) | Qhov siab tshaj plaws magnetic induction siv ntawm lub nruas nto (mT) | Muaj peev xwm

(t / h) | Hwj chim

(kW) | Suab nrov dB (A) | qhov hnyav (Kg) |

| JCT1024 | 1050 X 2400 hli |

Raws li cov ntxhia (100-600) | 25-50 | 11 |

≤ 75 | 5 250 |

| JCT1030 | 1050x3000 | 30-60 | 11 | 6700 ib | ||

| JCT1224 | 1200 X 2400 | 40-70 : kuv | 15 | 7200 ib | ||

| JCT 1230 | 1200 X 3000 | 50-80 | 15 | 10000 | ||

| JCT 1236 | 1200x3600 | 60-90 | 22 | 14 000 | ||

| JCT1240 | 1200 X 4000 | 75-110 : kuv | 22 | 16 000 | ||

| JCT1245 | 1200 X 4500 | 85-120 : kuv | 22 | 19000 Nws | ||

| JCT1530 | 1500x3000 | 70-100 ib | 22 | 15500 Nws | ||

| JCT1540 | 1500x4000 | 90-130 : kuv | 30 | Xyoo 19500 | ||

| JCT1545 | 1500x4500 | 100-150 | 30 | 22 000 | ||

| JCT1550 | 1500 X 5000 | 120-160 : kuv | 30 | 24500 Nws |

Nco tseg: 1. Thov muab cov qauv ore rau kev xaiv cov khoom siv, txhawm rau txiav txim siab qhov kev sib cais zoo tshaj plaws los ntawm kev sim sib nqus sib nqus.

Rau qhov kev hloov pauv tshiab hauv cov txheej txheem txiaj ntsig kev tsim kho tshiab

JCTN Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Tshuab Ua ke nrog cov khoom sib nqus nplawm, cov khoom siv dej yaug, thiab cov khoom siv sib kis tau nruab nrog kev hloov pauv ceev ceev, kev tswj hwm ntawm JCTN Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Nqus Sib Tsoo cov hauj lwm rau cov ntxhia ua cov ntsuas. Nyob rau hauv cov txheej txheem tau txais txiaj ntsig, nws tuaj yeem paub:

1) 、 Tau txais qhov tsim nyog mloog ua ntej tom qab thawj theem ntawm kev sib tsoo, kom paub tseeb tias "Tau ntxov";

2) 、 Ua kom cov seem seem ua ntej sib tsoo, thiab paub tias "Tso nws thaum ntxov";

3) 、 Cov txheej txheem sib nqus tag nrho hloov cov txheej txheem rov qab flotation kom ua tiav "Ntau dua";

4) 、 Ib qho JCTN sib nqus sib nqus hloov ntau yam sib nqus sib nqus sib cais;

5) 、 Hloov cov khoom xaiv ib txwm muaj;

6) 、 Daim ntawv thov nyob rau hauv ultra-fine hlau ore.

Siv cov ntaub ntawv ntawm JCTN magnetic separator

Daim ntawv thov ntawm JCTN Sib Nqus Separator hauv Benxi Dongfangsanjiazi Mining Kev Lag Luam

Thawj theem ntawm JCTN1245 sib nqus sib nqus yog pub los ntawm cov dej ntws ntawm thawj theem ntawm cua daj cua dub, thiab kev sib tsoo fineness yog -200 mesh, accounting rau 80%. Cov ntaub ntawv siv teb ntawm ib theem ntawm JCTN1245 sib nqus sib nqus yog qhia hauv Table 1.

Table 1 Teb cov ntaub ntawv ntawm JCTN1245 magnetic separator

| khoom | Qib TFe /% | Tawm /% | TFe rov qab /% | MFe /% |

| Nco ntsoov | 48.45 Nws | 46.28 Nws | 81.54 ib | |

| Tailings | 9.45 Nws | 53.72 ib | 19.01 Nws | 0.30 Nws |

| Pub noj | 27.50 Nws | 100.00 Nws | 100.00 Nws |

Nws tuaj yeem pom los ntawm cov lus saum toj no uas thawj theem tau txais JCTN1245 sib nqus sib nqus, thiab qhov zoo yog -200 mesh, suav txog 80%, cov qib ore raw tau nce los ntawm 27.50% rau qib siab ntawm 48.45%, tailings sib nqus hlau yog 0.30%, thiab tailings sib nqus hlau yog tsawg dua 1.00% hauv cov lus teb rau cov neeg siv khoom.

Tag nrho ntawm 10 pawg ntawm JCTN1245 sib nqus sib nqus yog siv rau kev txheeb xyuas cov haujlwm hauv thawj theem ntawm qhov chaw. Kev sib cais ntawm cov khoom siv no tsis yog tsuas yog txhim kho qib ntawm kev mloog zoo, tab sis kuj cuam tshuam rau feem ntau ntawm cov tailings, txo qhov kev sib tsoo ntawm theem ob, thiab txuag hluav taws xob, kev siv ntawm qhov chaw zoo thiab tau txais kev qhuas los ntawm cov neeg siv khoom.

Cov khoom noj khoom haus ntawm theem thib ob JCTN1245 sib nqus sib nqus sib nqus yog qhov dej ntws ntawm lub tshuab hluav taws xob thib ob, thiab kev sib tsoo zoo yog -400 mesh, suav txog 90%. Cov ntaub ntawv siv teb ntawm theem thib ob JCTN1245 sib nqus sib nqus yog qhia hauv Table 2.

Table 2 Teb cov ntaub ntawv ntawm theem thib ob JCTN1245 sib nqus sib nqus cais

| khoom | Qib TFe /% | Tawm /% | TFe rov qab /% | MFe /% |

| 精矿 | 63.83 ib | 79.01 Nws | 95.79 ib | |

| 尾矿Tailings | 10.57 Nws | 20.99 Nws | 4.21 | 0.60 ib |

| 给 矿 Pub noj | 52.65 ib | 100.00 Nws | 100.00 Nws |

Nws tuaj yeem pom los ntawm cov lus saum toj no uas theem ob tau txais JCTN1245 sib nqus sib nqus, thiab qhov zoo yog -400 mesh, suav txog 90%, qib ore raw tau nce los ntawm 52.65% rau qib siab ntawm 63.83%, tailings sib nqus hlau yog 0.60%. thiab tailings sib nqus hlau yog tsawg dua 1.00% hauv cov lus teb rau cov neeg siv khoom.

Tag nrho ntawm 10 JCTN1245 magnetic separators yog siv nyob rau theem ob ntawm qhov chaw rau kev ua haujlwm sib cais. Los ntawm kev sib cais ntawm cov khoom siv no, qib ntawm cov concentrate ore xav tau los ntawm cov neeg siv khoom yog nyob nruab nrab ntawm 61.00% thiab 65.00%, thiab cov hlau nplaum hlau ntawm tailings tsawg dua 1.00%. Muab piv rau kev siv cov khoom sib cais hauv cov koob, ib qho refiner thiab slag-tshem tawm cov hlau nplaum sib nqus tuaj yeem hloov tau ob qho tib si sib nqus sib nqus, txo qhov chaw hauv pem teb thiab cov nqi khiav lag luam.