Muaj Mineral Separation- Npua Ntiv Nplhaib High Gradient Electromagnetic Separator (LHGC-WHIMS, Sib Nqus Sib Nqus: 0.4T-1.8T)

Daim ntawv thov

Cov khoom no tuaj yeem siv rau kev tshem tawm impurity thiab purification ntawm non-metallic minerals xws li quartz, feldspar, nepheline ore thiab kaolin.

Txhim kho

| Roj-dej txias tshuab ntawm coil | Lub neej ntev integrated magnetic matrix |

| Flushing dej ntxhia tso tawm system | Ua kua theem tsis siv neeg tswj qhov system |

| Kub tswb tiv thaiv qhov system | Cooler leakage tswb system |

| Tsis siv neeg lubrication system | Intelligent remote monitoring system |

LHGC Qhov Zoo Tshaj Plaws Ntiv Ntiv Nplhaib WHIMS

| Ib txwm ntsug nplhaib WHlMS concems | LHGC Solutions |

| Lub kauj siv hollow hlau thiab dej txias txoj kev. Sab hauv phab ntsa ntawm cov hlau yog ib qho yooj yim los tsim cov txiv qaub nplai, thiab nws yuav tsum tau ntxuav cov kua qaub tsis tu ncua, tus nqi tsis ua haujlwm yog siab, thiab lub coil lub neej luv luv. | Lub kauj yog raus rau hauv cov roj kom txias, thiab txais yuav yuam kom loj-flow sab nraud ncig, uas muaj ceev cua sov dissipation, tsawg kub nce thiab tsis muaj txij nkawm. Lub plhaub plhaub tau txais cov qauv kaw tag nrho, uas tsim nyog rau ntau qhov chaw hnyav. |

| Cov pas nrig matrix ntog yooj yim | Lub matrix adopts ib-thooj los ntawm-hom qauv.and cov rods nruab nrab tsis poob; kho lub log phaj txais lub conical qauv tsim, uas muaj kev sib txuas siab zog thiab tsis yooj yim rau tawg. |

| Slurry ntws | Ultrasonic kua theem nrhiav tau txais yuav, uas yog txuas nrog lub tshuab hluav taws xob kom tau txais kev kho cov dej sib cais. |

| Kev tuav lubrication, qib kev nyab xeeb qis | Idle iav tsis siv neeg lubrication, nyab xeeb thiab txhim khu kev qha |

| Kev tuav haujlwm thiab kev saib xyuas, kev siv zog ntau | Kev txawj ntse tswj, ua haujlwm tsis tu ncua |

Lub LHGC roj-dej txias ntsug nplhaib siab gradient sib nqus sib nqus cais (WHlMS) siv cov sib nqus quab yuam, pulsating kua thiab lub ntiajteb txawj nqus tsis tu ncua cais cov hlau nplaum thiab tsis sib nqus. Nws muaj qhov zoo ntawm kev ua haujlwm loj, muaj txiaj ntsig zoo thiab rov ua haujlwm zoo, me me thermal attenuation ntawm magnetic teb, tag nrho tawm, thiab qib siab ntawm kev txawj ntse.

LHGC ntsug nplhaib siab gradient sib nqus sib nqus cais (WHlMS) yog txhim khu kev qha thiab yooj yim rau kev khiav lag luam thiab tswj, thiab Internet ntawm Yam thiab Cloud Platform Technology tau siv los ua kom paub txog kev ua haujlwm tsis siv neeg ntse, Los sib piv nrog cov tsoos WHIMS, LHGC txais yuav ntau tus. cov thev naus laus zis tshiab thiab cov txheej txheem, uas txhim kho kev ua haujlwm tau zoo, kev sib cais qhov tseeb thiab qhov kev tshem tawm ntawm tus nqi qis, nrog rau kev saib xyuas qis dua thiab cov nqi khiav lag luam.

Txoj Cai Kev Ua Haujlwm

Lub slurry yog nkag mus rau lub hopper pub los ntawm cov yeeb nkab pub, thiab nkag mus rau hauv lub magnetic matrix ntawm lub rotating nplhaib raws cov slots nyob rau hauv lub Upper magnetic ncej. Lub magnetic matrix yog magnetized, thiab high gradient magnetic teb yog generated ntawm nws nto. Cov khoom sib nqus yog nyiam nyob rau saum npoo ntawm cov hlau nplaum sib nqus, thiab raug coj mus rau qhov chaw tsis sib nqus nyob rau sab saum toj nrog kev sib hloov ntawm lub nplhaib, thiab tom qab ntawd ntws mus rau hauv cov hopper los ntawm cov dej ntws tawm. Cov tsis-magnetic particles fiow rau hauv cov khoom uas tsis yog-magnetic collection hopper raws cov slots nyob rau hauv lub qis magnetic ncej yuav tsum tau tawm.

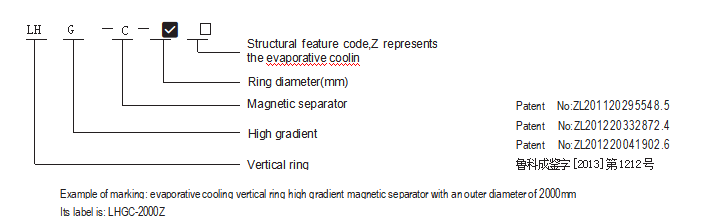

Qauv piav qhia

Cov yam ntxwv

◆ Huate nqa tawm lub computer simulation magnetic teb xam, tsim nyog tsim ntawm magnetic Circuit Court, me me poob ntawm magnetic zog, thiab lub magnetic teb lub zog yuav ncav cuag 1.7T.

◆ Lub excitation coil txais ib txheej txheej stereo winding qauv, uas muaj peev xwm hu rau lub evaporative txias nruab nrab nrog txhua feem ntawm lub kauj, zoo heev txhim kho lub tshav kub dissipation muaj peev xwm ntawm lub kauj.Cov qauv yog siab heev thiab kev khiav hauj lwm yog txhim khu kev qha.

◆ Txais cov cua txias nruab nrab ntawm cov rwb thaiv tsev siab thiab qhov kub ntawm qhov tsim nyog, uas txhim kho cov hluav taws xob rwb thaiv tsev ntawm cov kauj.

◆ Lub kauj siv lub thev naus laus zis thev naus laus zis thev naus laus zis rau kev ua kom txias, nrog kev ua haujlwm siab ntawm cov cua sov dissipation. Ua haujlwm kub tsis tshaj 48 ℃ , thiab cov khoom kub sib txawv tsis muaj qhov kub hauv zos.

◆ Lub evaporative cua txias nws tus kheej ncig lub cev muaj kev hloov kho tus kheej zoo thiab kev tswj tus kheej muaj peev xwm, nrog qhov sib txawv me me ntawm cov hlau nplaum sib nqus ntawm lub xeev txias thiab kub, thiab cov coil ua haujlwm kub tsis cuam tshuam los ntawm ib puag ncig sab nraud.

◆ Lub kauj ua haujlwm tau ntev nyob rau hauv qhov kub tsis tshua muaj siab, uas ua rau qeeb qeeb ntawm kev laus ntawm lub kauj thiab ua kom lub neej ntev ntawm cov khoom sib nqus sib nqus. Kev ua haujlwm muaj kev nyab xeeb thiab txhim khu kev qha.

◆ Lub kauj siv cov qauv kaw tag nrho, uas tuaj yeem hloov mus rau ntau qhov chaw ua haujlwm hnyav.

◆ High sib cais efficiency.Nws muaj ib tug dav adaptability rau qhov hloov pauv ntawm pub particle loj, pub concentration, thiab qib pub.

◆ Cov nplua nuj ore piv yog loj thiab tus nqi rov qab yog siab.

Technical Parameters Thiab Main Performance Indicators

Tus qauv xaiv txoj kev: Nyob rau hauv txoj cai, cov qauv xaiv ntawm cov cuab yeej yog raug rau tus nqi ntawm cov ntxhia slurry. Thaum sib cais cov ntxhia siv cov khoom siv zoo li no, cov slurry concentration muaj qee yam cuam tshuam rau cov ntxhia ua index. Kom tau txais cov ntxhia ua haujlwm zoo dua, thov txo cov slurry concentration kom zoo. Yog hais tias qhov piv ntawm cov khoom sib nqus nyob rau hauv cov pob zeb hauv av yog siab me ntsis, lub peev xwm ua haujlwm yuav raug txwv rau tag nrho cov khoom sib nqus ntawm cov khoom siv hlau nplaum los ntawm cov hlau nplaum sib nqus, nyob rau hauv rooj plaub, cov khoom noj concentration yuav tsum raug txo kom tsim nyog.