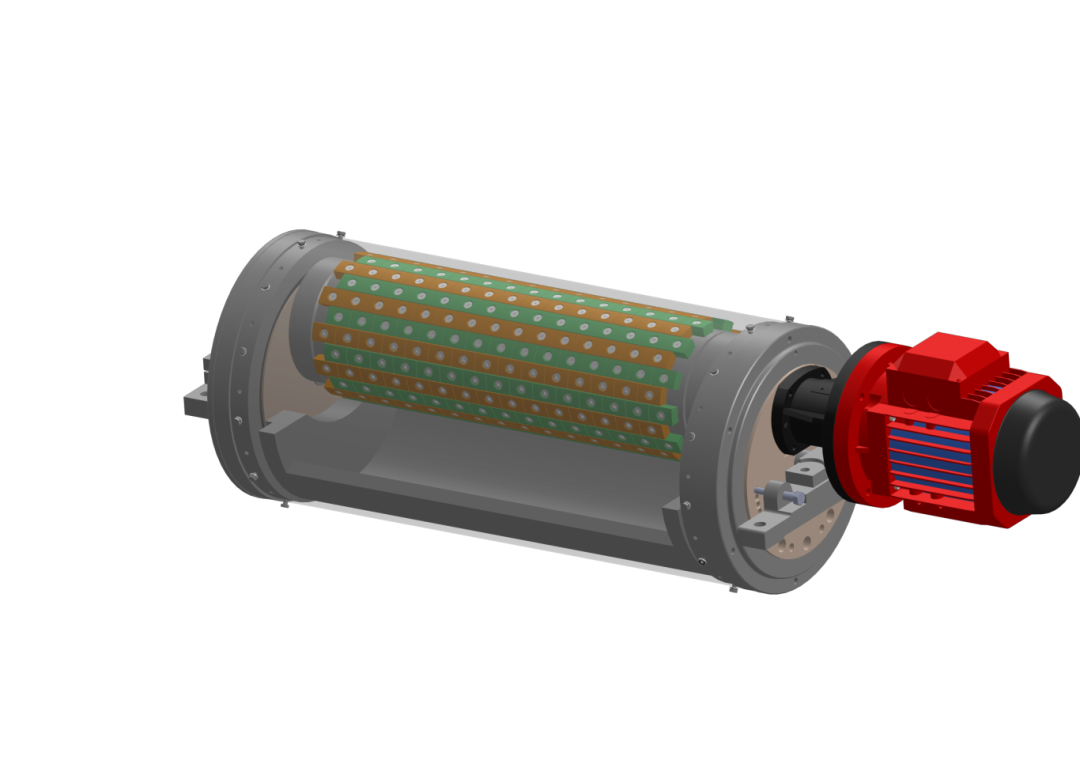

Eddy Current Separator muaj feem ntau ntawm lub nruas sib nqus thiab cov khoom siv thauj khoom (nrog rau cov hlua conveyor, tsav nruas, thiab txo cov motors). Nws yog feem ntau siv rau kev txheeb xyuas thiab rov qab ntau yam hlau tsis muaj hlau xws li tooj liab thiab txhuas los ntawm cov khoom siv khib nyiab xws li hluav taws xob pov tseg, lub qhov rais qub thiab cov qhov rooj, thiab cov tsheb khib nyiab. Qhov kev sib cais no ua kom muaj txiaj ntsig zoo, txo kev siv zog ua haujlwm, thiab ua tiav kev ua haujlwm ntawm ntau dua 98%.

Lub eddy tam sim no separator muaj lub ntsiab chav tsev, vibratory feeder, thiab tswj lub hwj chim qhov chaw.

Eddy tam sim no sib cais yog ib qho cuab yeej sorting raws li cov khoom sib txawv. Nws siv ob lub ntsiab lus tseem ceeb ntawm lub cev: kev hloov magnetic teb induces alternating hluav taws xob teb (electromagnetic induction), thiab tam sim no-nqa conductors tsim ib magnetic teb (Biot-Savart txoj cai).

Thaum lub sijhawm ua haujlwm, lub tshuab cais ua kom muaj qhov sib txawv ntawm qhov sib nqus sib nqus ntawm qhov chaw ntawm cov menyuam sorting. Thaum cov hlau tsis muaj hlau hla dhau ntawm daim teb no, lawv ua rau cov eddy tam sim no. Cov tam sim no tsim ib qho chaw sib nqus tawm tsam thawj qhov chaw, ua rau cov hlau (xws li tooj liab thiab txhuas) dhia mus rau pem hauv ntej vim muaj kev sib nqus sib nqus, sib cais lawv los ntawm cov khoom tsis yog hlau.

Cov ntawv thov suav nrog:

- Npuag steel crushing nroj tsuag: cais cov hlau tsis-ferrous los ntawm steel scraps.

- Pib dismantling thiab crushing nroj tsuag: cais cov hlau uas tsis yog-ferrous los ntawm cov khoom crushed.

- Cov khoom siv hluav taws xob siv hluav taws xob rov ua dua: Rov qab cov hlau los ntawm cov khoom hluav taws xob hauv hluav taws xob.

- Kev lag luam iav rov ua dua tshiab: Tshem tawm cov kaus mom txhuas thiab txhuas lossis tooj liab alloys los ntawm cov khoom iav crushed.

- Cov khoom pov tseg hauv tsev ua ntej sorting: cais cov kaus poom, lub kaus mom, thiab tooj liab thiab txhuas alloys ntawm cov khib nyiab hauv tsev.

- Cov khoom siv hluav taws xob hauv tsev siv hluav taws xob rov ua dua: cais cov hlau tsis muaj hlau los ntawm cov khoom seem incineration.

- Kev lag luam ntawv rov ua dua tshiab: txheeb cov hlau tsis muaj hlau los ntawm cov ntawv seem.

- Qhov rooj thiab qhov rais crushing thiab aluminium template crushing nroj tsuag: cais txhuas thiab lwm yam hlau los ntawm cov ntaub ntawv.

- Lwm lub sijhawm: cais lwm cov hlau tsis muaj hlau los ntawm cov khoom tsis yog hlau.

Lub eddy tam sim no separator tsim los ntawm huate txais ib tug tshwj xeeb kev npaj ntawm tib-ncej ob-kab thiab staggered configuration, maximizing magnetic teb siv thiab eddy tam sim no lub zog. Qhov kev tsim no ua rau muaj txiaj ntsig zoo rau kev sib cais ntawm cov hlau thiab cov khoom siv rov ua dua tshiab.

Cov yam ntxwv tseem ceeb technical:

- Kev ua haujlwm yooj yim rau kev sib cais tsis siv neeg hlau / tsis yog hlau.

- Ib qho yooj yim installation, sib xws nrog cov kab tshiab lossis uas twb muaj lawm.

- High-siv magnetic teb mus txog 3000-3500 Gauss, ob npaug rov qab tus nqi piv rau cov qauv cais.

- Kev hloov kho yooj yim rau kev txheeb xyuas zoo heev.

- Tsawg zog noj thiab ib puag ncig tus phooj ywg.

- Muaj peev xwm sorting cov ntaub ntawv ntawm ntau qhov sib txawv raws li cov kev taw qhia kev sib hloov.

Tam sim no, huate's eddy cov cais tam sim no tau siv dav hauv tsev thiab xa tawm mus rau ntau lub teb chaws thiab cheeb tsam, tau txais kev qhuas los ntawm ntau tus neeg siv khoom thoob ntiaj teb.

Huate Recycled Aluminium Ntau Lawm Kab

Post lub sij hawm: Jun-20-2024