Peb lub teb chaws cov khoom siv hlau hlau yog nplua nuj nyob rau hauv reserves thiab ntau yam, tab sis muaj ntau yam lean ores, ob peb nplua nuj ores, thiab nplua-granularity. Muaj ob peb ores uas tuaj yeem siv ncaj qha. Ib tug loj npaum li cas ntawm ore yuav tsum tau ua tiav ua ntej lawv yuav siv tau.Rau lub sij hawm ntev, muaj ntau thiab ntau nyuaj beneficiation ntawm cov xaiv ores, qhov beneficiation ratio tau ua loj thiab loj, cov txheej txheem thiab cov khoom tau ua ntau thiab ntau txoj kev, tshwj xeeb tshaj yog cov nqi sib tsoo tau pom tias muaj kev nce ntxiv.Tam sim no, cov chaw ua haujlwm feem ntau siv cov kev ntsuas xws li kev sib tsoo ntau dua thiab sib tsoo tsawg, thiab kev xaiv ua ntej thiab pov tseg cov pov tseg ua ntej sib tsoo, uas tau ua tiav cov txiaj ntsig zoo kawg li.

Feem ntau hais lus, qhuav ntuav before sib tsoo yog qhov zoo dua nyob rau hauv cov xwm txheej hauv qab nonws:

(1) Ibthaj chawqhov twg cov dej tsis txaus, dej rau kev txhim kho mining tsis tuaj yeem lav tau, ua rau qhov muaj peev xwm ntawm cov pob zeb ntub dej sib cais tsis siab. Yog li ntawd, nyob rau hauv cov cheeb tsam no, qhuav pre-xaiv txoj kev yuav raug txiav txim siab ua ntej.

(2) Nws yog ib qho tsim nyog los txo qhov ntim ntawm tailings slurry thiab txo qhov siab ntawm lub pas dej tailings. Qhov tseem ceeb yuav muab rau kev xaiv qhuav ua ntej thiab pov tseg pov tseg.

(3) Kev qhuav qhuav ntawm cov khoom loj-particle muaj peev xwm ua tau ntau dua li kev sib cais dej.

(4) Qhuav ntuav feem ntau muab faib ua ob peb theem:

Qhuav ntawm coarsely crushed khoom nrog ib tug siab tshaj particle loj ntawm 400~125 hli, Qhuav polishing ntawm nruab nrab-crushed khoom nrog ib tug siab tshaj particle loj ntawm 100-50 hli, Zoo crushing thiab qhuav polishing nrog ib tug siab tshaj particle loj ntawm 25~5 hli, Ntxiv rau qhov qhuav polishing ntawm cov khoom crushed los ntawm high-pressure roller mills, uas yog tam sim no dav siv, cov qauv ntawm cov khoom xaiv yog txawv.

Cov khoom sib cais qhuav rau cov khoom siv nrog qhov siab tshaj plaws particle loj ntawm 20 mm lossis ntau dua

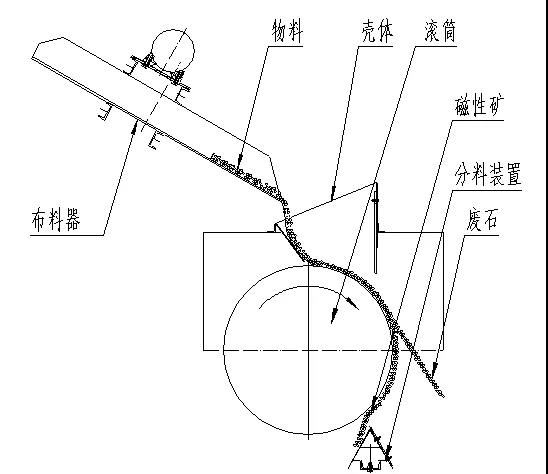

Rau qhuav polishing ntawm ore nrog lub siab tshaj plaws particle loj ntawm 20 hli lossis ntau dua, CTDG series ruaj khov hlau nplaum qhuav cov hlau nplaum sib nqus yog tam sim no siv dav tshaj plaws.

Cov hlau nplaum tas mus li qhuav bulk sib nqus sib nqus sib nqus yog siv dav hauv cov mines metallurgical thiab lwm yam lag luam kom tau raws li qhov xav tau ntawm cov mines loj, nruab nrab thiab me. Lawv yog siv rau kev xaiv ua ntej ntawm cov ntaub ntawv nrog qhov siab tshaj plaws particle loj ntawm tsis ntau tshaj 500 mm tom qab crushing nyob rau hauv lub sib nqus sib cais cog. Txhawm rau rov kho cov qib geological ntawm cov pob zeb pov tseg, nws tuaj yeem txuag hluav taws xob thiab txo kev noj, thiab ua kom muaj peev xwm ua tiav ntawm cov khoom siv; Nws yog siv rau hauv qhov chaw nres tsheb kom rov qab tau cov hlau nplaum hlau los ntawm cov pob zeb khib nyiab los txhim kho kev siv cov khoom siv ore; nws yog siv los rov qab hlau hlau los ntawm steel slag; nws yog siv rau hauv cov khib nyiab pov tseg los txheeb xyuas cov khoom siv hlau.

Cov hlau nplaum tas mus li qhuav bulk sib nqus sib nqus feem ntau yog siv cov hlau nplaum sib nqus rau kev sib cais, cov ore yog tusyees pub rau txoj siv tawv thiab thauj mus rau qhov chaw sorting nyob rau sab sauv ntawm lub nruas sib nqus ntawm qhov nrawm nrawm. cov minerals yog adsorbed rau ntawm qhov chaw ntawm lub nruas sib nqus siv, khiav mus rau sab qis ntawm lub nruas thiab tawg tawm ntawm qhov chaw sib nqus, thiab poob rau hauv cov concentrate tank los ntawm lub ntiajteb txawj nqus. Cov pob zeb pov tseg thiab cov hlau tsis muaj zog hlau nplaum tsis tuaj yeem nyiam los ntawm lub zog sib nqus thiab tuav lawv cov inertia. Nws tau muab pov tseg nyob rau hauv pem hauv ntej ntawm lub partitioning partitioning thiab poob rau hauv lub tailing trough.

Los ntawm cov qauv kev pom, cov hlau nplaum tas li qhuav cov hlau nplaum sib nqus sib nqus feem ntau suav nrog tsav lub cev muaj zog, elastic pin txuas, tsav reducer, hla swb txuas, sib nqus nruas sib nqus thiab sib nqus hloov kho reducer.

Cov ntsiab lus technical

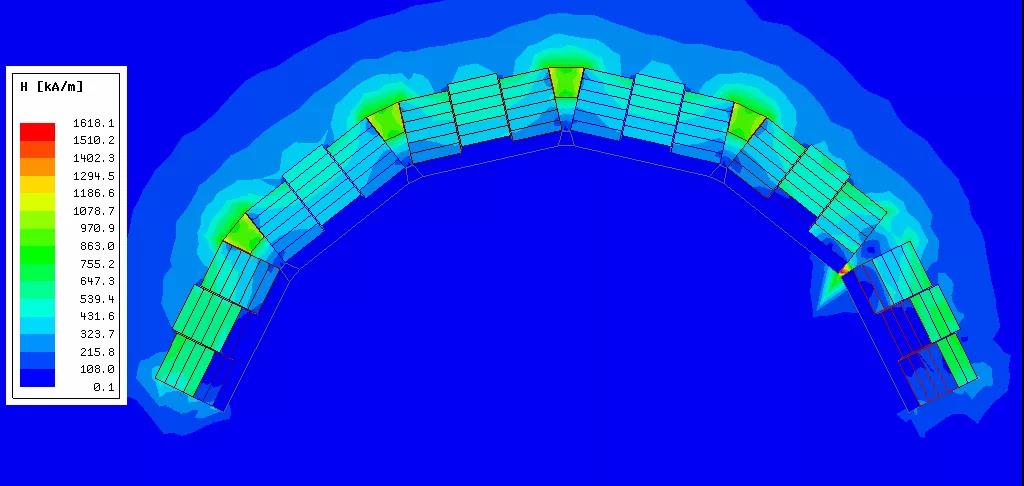

(1) Rau qhuav ntuav ntawm coarsely crushed khoom nrog ib tug siab tshaj particle loj ntawm 400-125 mm. Vim lub loj ore loj, txoj siv conveys ib tug loj npaum li cas tom qab ntxhib crushing, thiab lub Upper ib feem ntawm txoj siv conveyor nkag mus rau hauv lub nruas sorting cheeb tsam.In thiaj li ua tau ib tug tsim nyog pov tseg cov nyhuv thiab txo cov hlau nplaum hlau cov ntsiab lus ntawm tailings, Lub nruas hlau nplaum nyob rau theem no yuav tsum muaj qhov sib nqus loj dua qhov tob, kom cov khoom loj ntawm cov ore tuaj yeem ntes tau.Lub ntsiab lus tseem ceeb ntawm cov khoom tsim nyob rau theem no: ①Qhov loj ntawm cov menyuam txoj kab uas hla, qhov zoo dua, feem ntau mus txog 1 400 mm lossis 1 500 mm.② Txoj siv dav dav dav li qhov ua tau. Qhov siab tshaj plaws tsim dav ntawm txoj siv tam sim no yog 3 000 hli; txoj siv sia ntev li ntev tau nyob rau hauv qhov ncaj ncaj ze ntawm lub taub hau ntawm lub nruas, kom cov khoom txheej nkag mus rau hauv qhov chaw sib cais yog thinned.③Larger magnetic nkag qhov tob. Siv cov sorting ntawm ore hais nrog qhov siab tshaj plaws particle loj ntawm 300-400 mm ua piv txwv. Feem ntau, qhov sib nqus ntawm qhov sib nqus ntawm qhov kev ncua deb ntawm 150-200 mm ntawm lub nruas nto los ntawm lub nruas nqus qhov chaw mus rau lub nruas nto yog ntau dua 64kA / m, raws li qhia hauv daim duab 1. 1.④ Qhov sib txawv ntawm cov phaj faib thiab cov nruas yog ntau tshaj 400 mm thiab yog adjustable. ⑤ Kev ua hauj lwm ceev ntawm lub nruas yog adjustable, thiab kev hloov ntawm lub sib nqus declination lub kaum sab xis thiab cov kev hloov ntawm cov distributing ntaus ntawv ua lub sorting Performance index zoo.

Daim duab 1 Magnetic field cloud map

Table 1 Sib nqus teb siv ntawm ib qho kev ncua deb ntawm lub rooj sib nqus kA / m

Nws tuaj yeem pom los ntawm Table 1 tias qhov sib nqus ntawm qhov sib nqus ntawm qhov deb ntawm 200 hli los ntawm qhov chaw sib nqus yog 81.2 kA / m, thiab qhov sib nqus ntawm qhov sib nqus ntawm qhov deb ntawm 400 hli los ntawm qhov chaw sib nqus. 21.3 kA / m.

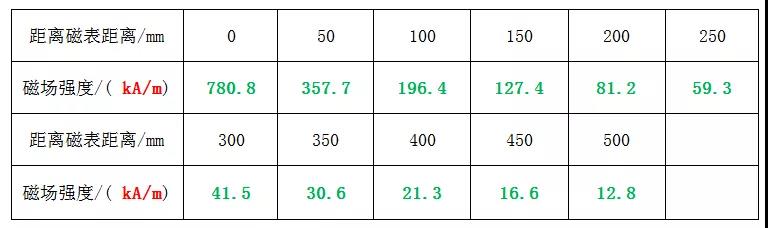

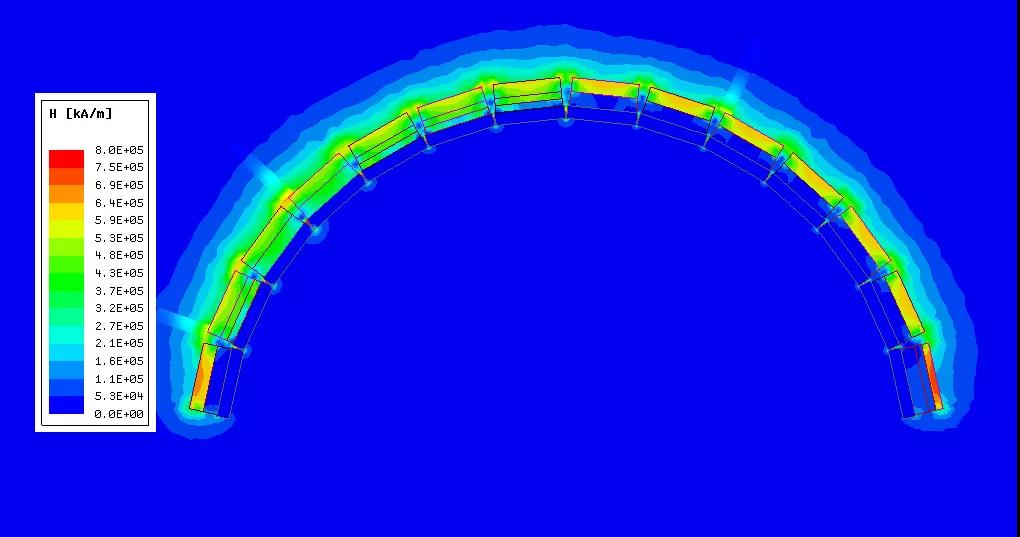

(2) Rau cov polishing qhuav ntawm cov khoom nruab nrab crushed nrog lub siab tshaj plaws particle loj ntawm 100-50 hli, vim lub finer particle loj thiab thinner cov ntaub ntawv txheej, tsim tsis thiab ntxhib crushing qhuav xaiv yuav kho kom haum:①Txoj kab uas hla ntawm lub nruas yog 1 000, 1 200, 1 400 mm.②Txoj siv dav dav yog 1 400, 1 600, 1 800, 2 000 mm; txoj siv yog ntev li ntev tau nyob rau hauv qhov ncaj seem nyob ze ntawm lub taub hau ntawm lub nruas, kom cov khoom txheej nkag mus rau hauv sorting cheeb tsam yog thinned.③Loj sib nqus nqus qhov tob, noj cov sorting ntawm ore hais nrog ib tug siab tshaj particle loj ntawm 100 mm raws li ib tug piv txwv, feem ntau lub magnetic teb zog ntawm qhov deb ntawm 100-50 mm los ntawm lub nruas nto los ntawm lub nruas suction cheeb tsam mus rau lub nruas nto. ntau dua 64kA / m, raws li qhia hauv daim duab 2 thiab Table 2.④Qhov sib txawv ntawm lub phaj faib thiab lub nruas yog ntau tshaj 100 mm thiab yog adjustable.⑤Kev ua hauj lwm ceev ntawm lub nruas yog adjustable, thiab kev hloov ntawm lub sib nqus declination lub kaum sab xis thiab kev hloov ntawm lub distributing ntaus ntawv ua rau cov sorting Performance index pom zoo.

Daim duab 2 Magnetic field cloud map

Table 2 Sib nqus teb siv ntawm ib qho kev ncua deb ntawm lub rooj sib nqus kA / m

Nws tuaj yeem pom los ntawm Table 2 tias qhov sib nqus ntawm qhov sib nqus ntawm qhov deb ntawm 100 hli los ntawm qhov chaw sib nqus yog 105 kA / m, thiab qhov sib nqus sib nqus ntawm qhov nrug ntawm 200 hli los ntawm qhov chaw sib nqus. 30.1 kA / m.

(3) Rau qhuav polishing ntawm finely faib cov khoom nrog ib tug siab tshaj particle loj ntawm 25-5 hli, ib tug me me nruas txoj kab uas hla thiab ib tug me me sib nqus nkag mus rau qhov tob yuav raug xaiv nyob rau hauv tsim thiab xaiv, uas yuav tsis tham txog ntawm no.

Cov khoom siv ziab rau cov ntaub ntawv nrog qhov siab tshaj plaws particle loj tsawg dua 20 hli.

- MCTF series pulsating qhuav magnetic separator

MCTF series pulsating qhuav magnetic separator yog qhov nruab nrab lub zog sib nqus cov khoom sib nqus. Nws yog tsim rau cov mos mos xws li sandstone ore, xuab zeb ore, dej xuab zeb, hiav txwv xuab zeb, thiab lwm yam los yog crushed powdery lean ore nrog ib tug particle loj ntawm 20~0 hli. Concentration ntawm magnetic minerals thiab qhuav pre-xaiv ntawm finely crushed magnetite khoom.

1.2 Lub hauv paus ntsiab lus ua haujlwm

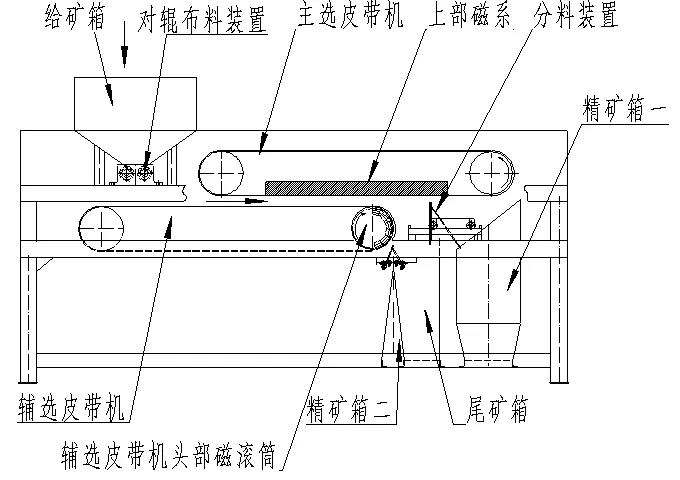

Lub hauv paus ntsiab lus ua haujlwm ntawm MCTF series pulsating qhuav magnetic separator yog qhia hauv daim duab 3.

Daim duab 3 Schematic daim duab ntawm lub hauv paus ntsiab lus ua hauj lwm ntawm MCTF hom pulsating qhuav magnetic separator

Siv lub hauv paus ntsiab lus uas cov ntaub ntawv sib nqus tuaj yeem raug nyiam los ntawm cov hlau nplaum tas li, ib qho kev sib nqus sib nqus semicircular nrog cov hlau nplaum loj dua yog teem rau hauv lub nruas los ntawm cov ntaub ntawv ntws.Thaum cov khoom ntws los ntawm cov hlau nplaum, cov hlau nplaum sib nqus tau raug ntes los ntawm cov khoom siv. muaj zog magnetic quab yuam thiab adsorbed nyob rau saum npoo ntawm lub semi-circular magnetic system.Thaum cov hlau nplaum sib nqus tau coj mus rau qhov qis uas tsis yog-magnetic los ntawm lub nruas rotating, lawv poob mus rau qhov hluav taws xob mloog zoo thiab tawm hauv qab qhov kev txiav txim ntawm lub ntiajteb txawj nqus. Cov hlau tsis muaj hlau nplaum lossis cov ore nrog qib hlau qis tuaj yeem ntws los ntawm cov hlau nplaum mus rau lub qhov hluav taws xob tailings nyob rau hauv qhov kev txiav txim ntawm lub ntiajteb txawj nqus thiab centrifugal quab yuam.

Los ntawm cov qauv kev pom, MCTF-hom pulsating qhuav sib nqus sib nqus cais feem ntau suav nrog cov khoom siv sib nqus hloov kho, lub nruas sib dhos, lub plhaub sab saud, plua plav npog, thav duab, cov khoom siv sib nqus, thiab cov khoom xa tawm.

Cov ntsiab lus technical

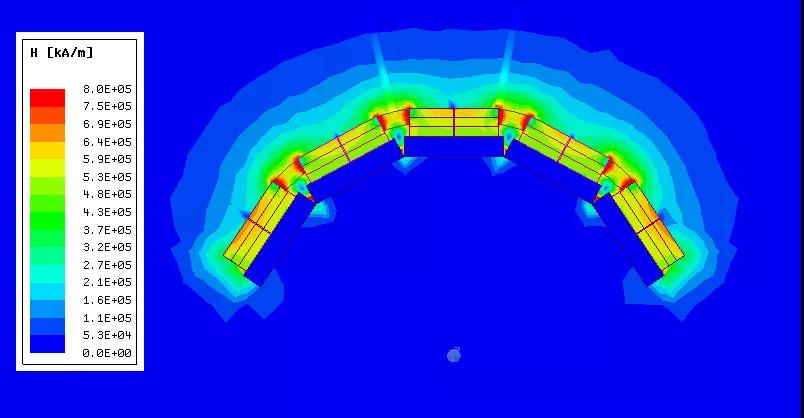

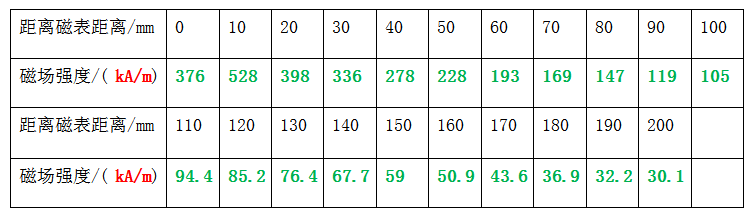

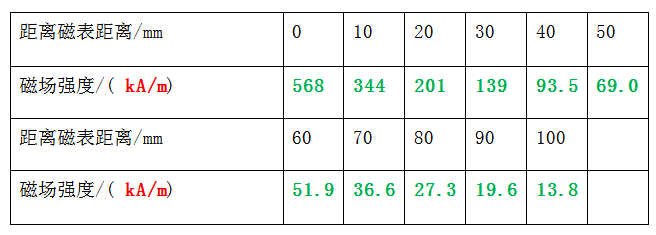

Cov ntsiab lus tseem ceeb ntawm cov qauv muaj xws li: ①Cov kab uas siv cov menyuam feem ntau yog 800, 1,000, thiab 1 200 mm; tus qauv tsim ua raws li lub hauv paus ntsiab lus hais tias lub finer lub particle loj sib haum mus rau lub me me txoj kab uas hla, thiab lub coarser lub particle loj sib haum mus rau lub loj lub cheeb ntawm lub nruas.② Qhov ntev ntawm lub nruas yog feem ntau tswj nyob rau hauv 3,000 mm. Yog tias lub nruas ntev dhau lawm, daim ntaub yuav tsis sib xws ntawm qhov ntev, uas yuav cuam tshuam rau kev sib cais.③ Raws li qhov loj me ntawm cov khoom yuav zoo dua, qhov sib nqus nkag qhov tob ntawm lub nruas yuav ntiav; tus naj npawb ntawm cov ncej sib nqus nce, uas yog qhov tsim nyog rau ntau qhov kev hloov pauv ntawm cov khoom siv thiab paub txog kev sib cais ntawm cov tailings refined ntawm cov khoom; Thaum lub thickness ntawm cov khoom txheej yog 30 hli, qhov kev ncua deb ntawm lub nruas nto yog 30 Qhov sib nqus ntawm qhov sib nqus ntawm mm yog 64kA / m, saib daim duab 4 thiab Table 3.④ Qhov sib txawv ntawm cov phaj faib thiab lub nruas yog ntau dua 20 mm thiab yog adjustable. ⑤ Txhawm rau kom ntseeg tau qhov sib txawv ntawm qhov ntev ntawm lub nruas, cov cuab yeej yuav tsum tau nruab nrog cov cuab yeej pabcuam xws li chute, vibrating feeder, kauv distributor lossis lub hnub qub distributor. noj kom muaj nuj nqis. ⑦ Kev ua hauj lwm ceev ntawm lub nruas yog adjustable, thiab kev hloov ntawm lub sib nqus declination lub kaum sab xis thiab kev hloov ntawm cov khoom faib khoom ua rau cov sorting Performance index zoo. Daim ntawv thov chaw ntawm MCTF pulsating qhuav sib nqus sib nqus sib nqus nrog vibrating feeder yog qhia hauv daim duab 5.

Daim duab 4 Magnetic field cloud map

Table 3 Sib nqus teb siv ntawm ib qho kev ncua deb ntawm lub rooj sib nqus kA / m

Nws tuaj yeem pom los ntawm Table 3 tias qhov sib nqus ntawm qhov sib nqus ntawm qhov deb ntawm 30 hli los ntawm qhov chaw ntawm qhov sib nqus yog 139kA / m, thiab qhov sib nqus ntawm qhov sib nqus ntawm qhov deb ntawm 100 hli los ntawm qhov chaw sib nqus yog 13.8. kA/m.

Daim duab 5 Daim ntawv thov chaw ntawm MCTF pulsating qhuav sib nqus sib cais nrog vibrating feeder

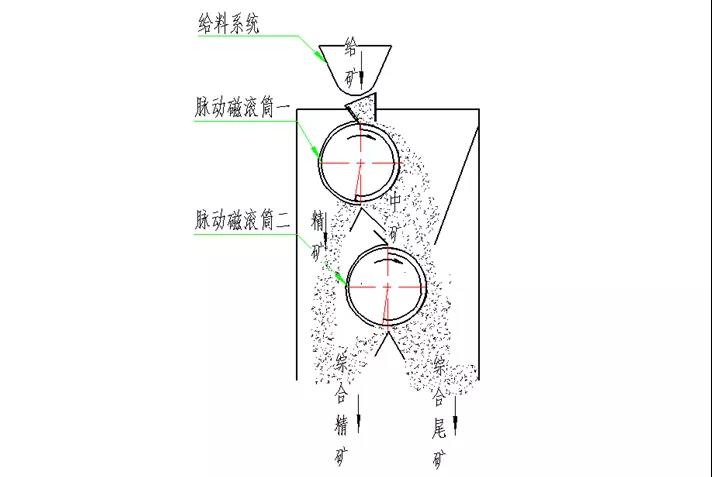

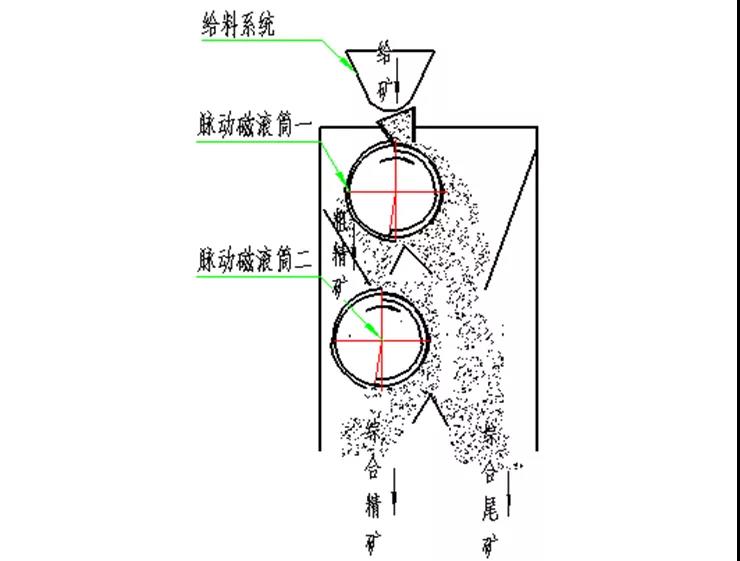

2.MCTF series ob lub nruas pulsating qhuav sib nqus separator

2.1 Lub hauv paus ntsiab lus ua haujlwm ntawm kev cheb ntxhib

Cov khoom siv nkag mus rau hauv cov ore los ntawm cov khoom noj. Tom qab cov ore yog txheeb los ntawm thawj lub nruas, ib feem ntawm cov concentrate yog thawj coj tawm. Cov tailings ntawm thawj nruas nkag mus rau lub nruas thib ob rau cheb, thiab cheb concentrate thiab thawj concentrate yog tov los ua qhov kawg concentrate. , Cov tailings uas scavenged yog qhov kawg tailings. Lub hauv paus ntsiab lus ua haujlwm ntawm ib qho cheb ntxhib yog qhia hauv daim duab 6.

2.2 Lub hauv paus ntsiab lus ua haujlwm ntawm ib qho ntxhib thiab ib qho zoo

Cov khoom siv nkag mus rau hauv cov ore los ntawm cov khoom noj. Tom qab cov ore tau txheeb los ntawm thawj lub nruas, ib feem ntawm cov tailings yog thawj zaug pov tseg. Lub concentrate ntawm thawj nruas nkag mus rau lub nruas thib ob rau xaiv, thiab lub nruas thib ob sorting concentrate yog qhov kawg concentrate. Qhov thib ob hnav khaub ncaws tailings yog muab tso rau hauv qhov kawg tailings. Lub hauv paus ntsiab lus ua haujlwm ntawm ib qho ntxhib thiab ib qho nplua yog qhia hauv daim duab 7.

Daim duab 7 Daim duab qhia txog kev ua haujlwm ntawm cov ntxhib thiab nplua

Cov ntsiab lus technical

Cov ntsiab lus ntawm 2MCTF series ob lub nruas pulsating qhuav magnetic separator: ①Lub hauv paus ntsiab lus tsim yog tib yam li MCTF series pulsating qhuav magnetic separator. ② Lub zog sib nqus ntawm lub raj thib ob yog ntau dua li ntawm thawj lub raj thaum thawj zaug ntxhib thiab thawj cheb; qhov sib nqus qhov sib nqus ntawm lub raj thib ob yog qis dua thawj lub raj thaum thawj zaug yog ntxhib thiab lwm yam zoo. Daim ntawv thov qhov chaw ntawm 2MCTF ob lub nruas pulsating qhuav sib nqus sib cais nruab nrog lub hnub qub zoo li cov khoom noj khoom haus thiab cov khoom siv ntsuas tsis siv neeg yog pom hauv daim duab 8.

Daim duab 8 Daim ntawv thov chaw ntawm 2MCTF ob lub nruas pulsating qhuav sib nqus cais nruab nrog lub hnub qub zoo li cov khoom noj khoom haus thiab tsis siv neeg ntsuas ntsuas.

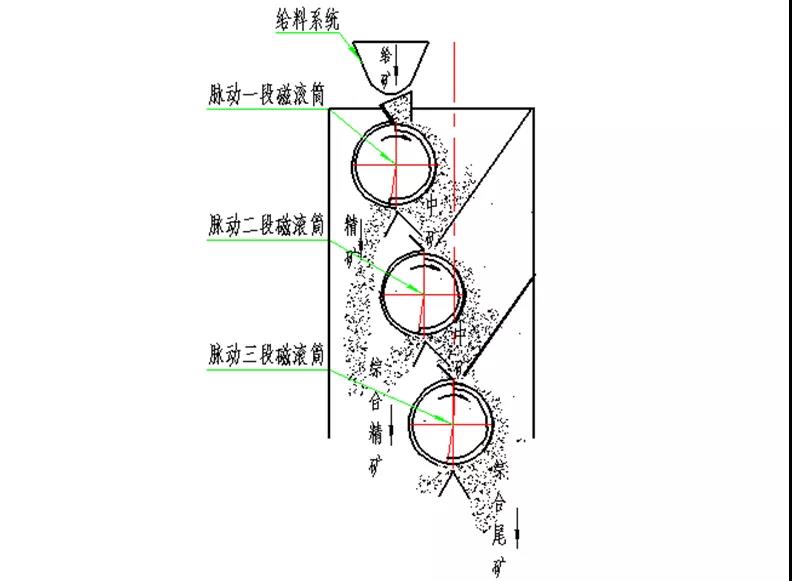

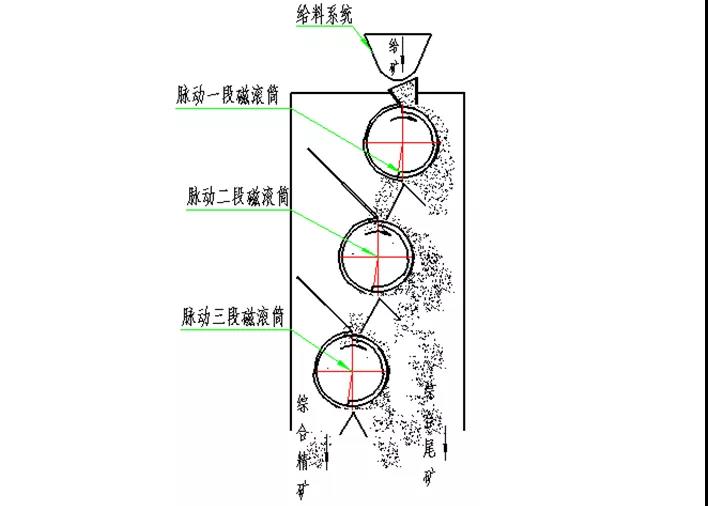

3.3MCTF series peb-nruas pulsating qhuav magnetic separator

3.1 Lub hauv paus ntsiab lus ua haujlwm ntawm ib qho ntxhib thiab ob qhov cheb

Cov khoom siv nkag mus rau hauv cov ore los ntawm cov khoom noj khoom haus, cov ore yog txheeb los ntawm thawj lub nruas, thiab ib feem ntawm cov concentrate yog thawj zaug tawm. Cov tailings ntawm thawj nruas nkag mus rau lub nruas thib ob cheb, lub nruas thib ob tailings nkag mus rau lub nruas thib peb, thiab lub nruas thib peb tailings Rau qhov kawg tailings, lub concentrates ntawm thawj, thib ob, thiab thib peb chim yog merged mus rau hauv lub kawg concentrate. Lub hauv paus ntsiab lus ua haujlwm ntawm ib qho ntxhib thiab ob qhov cheb yog qhia hauv daim duab 9.

Daim duab 9 Schematic daim duab ntawm lub hauv paus ntsiab lus ua hauj lwm ntawm ib tug ntxhib thiab ob cheb

Cov khoom siv nkag mus rau hauv cov ore los ntawm cov khoom noj. Tom qab cov ore raug txheeb xyuas los ntawm thawj lub nruas, cov concentration nkag mus rau lub nruas thib ob rau kev sib cais ntxiv, lub nruas thib ob tau nkag mus rau qhov thib peb nruas sorting, thiab lub nruas thib peb yog qhov kawg concentrate. Cov tailings ntawm lub nruas thib ob thiab thib peb yog merged rau hauv qhov kawg tailings. Lub hauv paus ntsiab lus ua haujlwm ntawm ib qho ntxhib thiab ob qhov kev nplua yog qhia hauv daim duab 10.

Daim duab 10 Schematic daim duab ntawm kev ua hauj lwm hauv paus ntsiab lus ntawm ib tug ntxhib thiab ob nplua

Cov ntsiab lus technical

Cov ntsiab lus ntawm 3MCTF series peb-cov menyuam pulsating qhuav sib nqus sib nqus cais: ①Cov qauv tsim qauv yooj yim yog tib yam li MCTF series pulsating qhuav sib nqus sib nqus. ②Qhov sib nqus qhov sib nqus ntawm lub raj thib ob thiab lub raj thib peb nce nyob rau hauv kev txiav txim ntawm ib qho ntxhib thiab ob cheb; qhov sib nqus qhov sib nqus ntawm lub raj thib ob thiab lub raj thib peb txo qis hauv qhov kev txiav txim ntawm ib qho ntxhib thiab ob qhov zoo. Daim ntawv thov chaw ntawm 3MCTF series peb-nruas pulsating qhuav sib nqus sib nqus cais yog qhia hauv daim duab 11.

Daim duab 11 Daim ntawv thov chaw ntawm 3MCTF peb-nruas pulsating qhuav sib nqus sib nqus cais

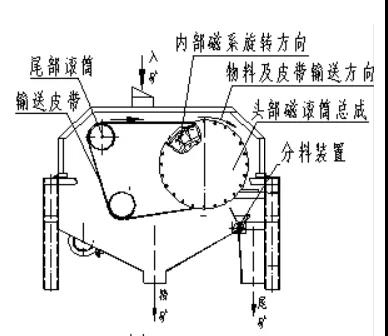

4. CTGY series mus tas li sib nqus rotating magnetic teb qhuav magnetic separator

Lub hauv paus ntsiab lus ua haujlwm ntawm CTGY series cov hlau nplaum ruaj khov rotating magnetic teb qhuav sib nqus sib nqus yog qhia hauv daim duab 12.

Daim duab 12 Lub hauv paus ntsiab lus ua haujlwm ntawm CTGY series mus tas li magnetic rotating magnetic field qhuav magnetic separator.

CTGY series ruaj khov hlau nplaum rotating magnetic teb pre-selector [3] txais kev sib nqus sib nqus, los ntawm ob pawg ntawm cov khoom siv sib nqus, paub txog qhov rov qab tig ntawm cov hlau nplaum thiab lub nruas, ua kom muaj kev hloov pauv sai, kom cov khoom sib nqus tuaj yeem ua tau. sib cais nyob deb. Qhov nruab nrab yog sib cais ntau dua los ntawm cov khoom tsis sib nqus thiab tsis muaj zog hlau nplaum.

Cov khoom ntog rau ntawm txoj siv conveyor los ntawm qhov chaw nres nkoj pub rau saum cov khoom noj, thiab txoj siv conveyor txav mus rau hauv qhov kev txiav txim ntawm lub tshuab sib cais, thiab cov hlau nplaum sib nqus rotating nyob rau hauv qhov kev taw qhia ntawm qhov kev txiav txim ntawm lub cev muaj zog (kwv yees rau txoj siv sia. ) Tom qab cov khoom raug coj mus rau hauv magnetic teb los ntawm txoj siv conveying, cov khoom sib nqus yog nruj nreem adsorbed ntawm txoj siv thiab raug rau cov hlau nplaum sib nqus ua kom muaj zog, ua rau tig thiab dhia, thiab "squeezing" cov khoom tsis sib nqus rau hauv sab sauv txheej ntawm cov khoom nyob rau hauv qhov kev txiav txim ntawm lub ntiajteb txawj nqus thiab centrifugal quab yuam. , Ceev nrooj nkag mus rau lub thawv tsis sib nqus. Cov khoom sib nqus yog adsorbed rau txoj siv thiab txuas ntxiv mus rau hauv qab lub nruas. Thaum nws tawm hauv qhov chaw sib nqus, nws nkag mus rau hauv lub thawv sib nqus nyob rau hauv qhov kev txiav txim ntawm lub ntiajteb txawj nqus thiab lub zog centrifugal kom paub txog kev sib cais zoo ntawm cov khoom sib nqus thiab cov khoom tsis sib nqus.

Cov ntsiab lus technical

Cov qauv yooj yim ntawm CTGY series mus tas li sib nqus rotating magnetic teb qhuav sib nqus sib cais muaj xws li thav duab, pub lub thawv, nruas, tailings lub thawv, mloog zoo lub thawv, sib nqus kis system, nruas kis tau tus mob, thiab lwm yam.

Cov ntsiab lus ntawm CTGY series mus tas li sib nqus sib nqus rotating magnetic teb qhuav sib nqus sib nqus cais: ①Cov txheej txheem sib nqus tsim tau txais kev sib nqus sib nqus sib nqus, lub sib nqus qhwv lub kaum sab xis yog 360 °, cov kev taw qhia ncig yog hloov pauv raws li NSN polarity, thiab cov cuab yeej sib nqus tshwj xeeb. yog siv. NdFeB wedge magnetic block pawg tau ntxiv ntawm cov pab pawg sib nqus kom ua rau lub nruas Lub zog yog nce ntau dua 1.5 npaug, thiab cov hlau nplaum sib nqus yog ob npaug rau tib lub sijhawm, uas ua rau muaj ntau qhov sib nqus thaum lub sij hawm sorting txheej txheem, thiab tuaj yeem muab pov tseg tsis muaj zog hlau nplaum thiab sib xyaw gangues hauv cov zaub mov.Qhov kev ua haujlwm siab, siab-coercivity, high-temperature thiab high-temperature-resistant tsis tshua muaj lub ntiaj teb neodymium hlau boron yog siv los ua cov hlau nplaum, thiab cov hlau nplaum hlau nplaum yog ua los ntawm cov khoom siv high-permeability DT3 hluav taws xob ntshiab hlau, uas zoo heev txhim kho cov permeability. Cov tub ntxhais ncej minimizes lub magnetic teb poob, thiab lub magnetic teb lub zog nyob rau saum npoo ntawm lub magnetic cylinder yog zoo txhim kho, uas pab txoj kev rov qab tus nqi ntawm cov ntaub ntawv ferromagnetic.②Lub nruas magnetic system yog zaus-hloov thiab ceev-tswj cais. Ob lub geared motors raug xaiv los tswj qhov ceev ntawm lub nruas thiab kev sib hloov ntawm cov hlau nplaum sib nqus raws li, thiab ob lub cev muaj zog yog tswj los ntawm ob lub inverters. Qhov ceev ntawm lub cev muaj zog tuaj yeem hloov pauv los ntawm kev kho qhov zaus ntawm lub cev muaj zog ntawm qhov xav tau, Los ntawm kev hloov cov kev sib hloov ceev ntawm lub nruas thiab kev sib hloov ceev ntawm cov hlau nplaum, tus naj npawb ntawm tumbling ntawm cov ntxhia hais yog tswj.③ Cov hlau nplaum ruaj khov rau cov menyuam chim yog ua los ntawm iav fiber reinforced yas ua los ntawm epoxy resin, uas tsis txhob cua sov ntawm cov menyuam thiab ua rau kom lub cev muaj zog lub zog vim cov nyhuv ntawm eddy tam sim no.

5. CXFG Series Suspended Sib Nqus Separator

5.1 Cov qauv tseem ceeb thiab lub hauv paus ntsiab lus ua haujlwm

Lub CXFG series ncua kev sib nqus sib nqus cais yog tsim los ntawm lub thawv pub, lub txee-cov menyuam faib khoom, lub ntsiab siv conveyor, ib qho kev pabcuam siv conveyor, lub tshuab sib nqus, cov khoom xa tawm, cov khoom siv nres, lub thawv mloog zoo, lub thawv tailings. , ib tug ncej thiab ib tug kis tau tus mob System muaj pes tsawg leeg.

Lub hauv paus ntsiab lus ntawm kev sib cais ntawm CXFG series ncua kev sib nqus sib nqus sib cais yog siv cov txheej txheem rau cov menyuam kom sib npaug ntawm cov khoom siv rau saum npoo ntawm txoj siv conveyor ntawm cov khoom siv siv conveyor. Qhov sib nqus system ntawm lub ntsiab siv conveyor yog nyob rau sab sauv ntawm cov khoom kom cais cov khoom muaj zog sib nqus. Nws tau khaws thiab xa mus rau lub thawv concentrate. Thaum cov ntaub ntawv tsis muaj zog hlau nplaum dhau los ntawm lub taub hau ntawm cov khoom siv sib nqus, lawv tau nqus los ntawm lub nruas los ntawm cov hlau nplaum hauv lub nruas, thiab poob rau hauv lub thawv concentrate tom qab tau muab cais tawm ntawm cov hlau nplaum raws li lub nruas tig. Cov pob zeb tsis sib nqus yog muab pov rau hauv lub thawv tailings nyob rau hauv qhov kev txiav txim ntawm inertial quab yuam ntawm kev txav thiab lub ntiajteb txawj nqus, thiaj li ua tiav lub hom phiaj ntawm kev txheeb xyuas. Lub hauv paus ntsiab lus ua haujlwm ntawm CXFG series ncua kev sib nqus sib nqus cais yog qhia hauv daim duab 13.

Daim duab 13 Lub hauv paus ntsiab lus ua haujlwm ntawm CXFG series ncua kev sib nqus sib nqus cais

Cov ntsiab lus technical

Cov ntsiab lus ntawm CXFG series ncua kev sib nqus sib nqus sib nqus cais: ①Siv cov txee-cov menyuam cov ntaub ntawv tuaj yeem tsis tsuas yog ua kom muaj kev sib xws ntawm cov txheej txheem ua haujlwm thiab cov khoom siv, tab sis kuj tuaj yeem cuam tshuam thiab pab cov crushing ntawm cov pob zeb loj. Muaj qee qhov sib txawv ntawm ob khub ntawm cov menyuam. Ib khub ntawm intermeshing gears yog tsav los tig synchronously thiab thim rov qab los ntawm qhov tsis tu ncua zaus txo lub cev muaj zog. Tus neeg siv tuaj yeem kho qhov ceev ntawm ob khub ntawm rollers raws li cov zis los kho cov nqi ntawm cov ore.② Lub ntsiab sib cais siv conveyor txais yuav qhib lub hom phiaj sib nqus, nrog ntau lub sib nqus ncej sib txuas. Planar magnetic system muaj qhov sib cais ntev thiab ntev ntawm magnetization, uas tsim ntau adsorption lub sij hawm rau magnetic ore. Thiab vim hais tias lub magnetic system nyob rau sab sauv ntawm cov ore, cov hlau nplaum nyob rau hauv lub sorting cheeb tsam, nws yog nyob rau hauv ib tug ncua kev kawm ntawv thiab xoob lub xeev, lub monomer yog adsorbed, tsis muaj inclusion phenomenon, thiab cov efficiency ntawm kev txhim kho qib yog. ntau dua li qhov nkhaus magnetic system.Cov hlau nplaum sib nqus txav raws cov ncej sib nqus thiab dhau los ntawm lub dav hlau sib nqus. Cov hlau nplaum hlau nplaum tau muab tso rau ntau zaus. Qhov zaus ntawm kev tig yog qhov loj thiab lub sij hawm ntev, uas yog qhov zoo los txhim kho qib ntawm cov hlau nplaum sib nqus.Nyob rau hauv cov txheej txheem sib nqus sib nqus, cov qauv tsim muaj qhov ntse thiab tsim nyog sib nqus sib txawv, thiab cov zaub mov yeej ib txwm nyob rau hauv qhov kev txiav txim ntawm ntau yam. polar magnetic ncej, uas zoo sib cais cov gangue thiab cov hlau tsis muaj hlau nplaum, yog li tau txais kev rov zoo tag nrho, kev txhim kho qib siab thiab txo tus Tsov tus tw khiav.③Cov khoom siv siv conveyor feem ntau yog siv los thauj cov zaub mov, thiab lub taub hau txais cov qauv sib nqus nruas rau cais me me. Cov menyuam siv cov qauv groove los tiv thaiv txoj hlua sib txawv.

Cov khoom lag luam uas tau hais los saum toj no tsim los ntawm Shandong Huate Magnetoelectric Technology Co., Ltd. Lawv muaj lawv tus kheej tsom ntsoov rau cov khoom tsim qauv kom tau raws li qhov yuav tsum tau muaj ntawm cov kev txheeb xyuas sib txawv, thiab lawv tau ua tiav tiav. Hauv ntau lub lag luam mining, nws tau ua lub luag haujlwm zoo hauv kev txuag hluav taws xob thiab txo kev siv thiab txhim kho kev ua haujlwm.

Kev lag luam mining yuav tsum xaiv cov khoom sib nqus sib nqus tsim nyog rau lawv tus kheej kev lag luam raws li qhov xwm txheej ntawm cov ore thiab cov txheej txheem thev naus laus zis txhawm rau txhim kho kev tsim khoom.

Cov khoom lag luam yuav tsum tsis tu ncua txhim kho thiab ua tiav cov kev ua tau zoo ntawm lawv cov khoom raws li cov kev xav tau ntawm kev lag luam mining, daws qee qhov teeb meem hauv kev siv tiag tiag, tsim cov khoom tsim nyog rau kev siv hauv kev lag luam, thiab txhawb kev tsim cov khoom siv sib nqus sib nqus.

Post lub sij hawm: Mar-17-2021