Steel slag, raws li qhov kawg pov tseg slag tsim los ntawm steel smelting, muaj cov hlau siab. Vim nws lub siab ntom ntom thiab siab ntom ntom ntom, nws tsis tuaj yeem nrov thiab siv hauv kev tsim kho kev tsim kho. Cov khoom siv hlau muaj txiaj ntsig tsis tau rov qab zoo, ua rau qee qhov pov tseg. Cov hlau slag yuav tsum tau siv dua thiab rov siv dua los ntawm cov txheej txheem sib nqus sib nqus, thiab ua tau raws li cov kev xav tau ntawm cov hmoov hlau qib uas yuav tsum tau ua los ntawm cov hlau uas muaj cov khoom siv rau blast furnace smelting, kom cov hlau slag tuaj yeem rov ua dua. Yuav siv tau zoo dua hauv kev tsim kho.

Tam sim no, ib qho txheej txheem sib nqus sib nqus yog ib txoj hauv kev ua tau zoo dua, thiab nws yog qhov tsim nyog los xaiv cov cuab yeej tsim nyog kom ua tiav cov hlau sib cais thiab rov ua haujlwm zoo. Lub steel slag yog hauv av kom paub txog nws dissociation, thiab tom qab ntawd los ntawm cov huab cua qhuav sib nqus sib cais ntawm cov hmoov ore, cov khoom noj ore, mloog zoo thiab tailings tau txais raws li, thiab tag nrho cov hlau qib yog soj ntsuam thiab soj ntsuam kom tau cov txheej txheem zoo tshaj plaws thiab cov khoom siv. tsis muaj. Muab kev txhawb nqa tsim nyog rau kev tsim khoom tiag tiag.

Steel slag zog

Steel slag yog cov khib nyiab pov tseg uas tsim los ntawm kev siv cov kua qaub-magnesium, cov txiv qaub nquag thiab lwm yam khoom siv rau kev ua kom tsis muaj paug thiab oxygen tshuab hauv cov txheej txheem steelmaking, yog li nws muaj cov hlau oxide siab, feem ntau 20% -40%, thiab FeO cov ntsiab lus yog ntau tshaj Fe2O3, qhov qub yog feem ntau 15% -25%, thaum tom kawg yog 5% -15%, ob qho tib si uas qhia tsis muaj zog hlau nplaum.

Cov khoom siv kuaj

Cov khoom siv kuaj tau txais FX0665 hmoov ore huab cua qhuav sib nqus sib nqus cais ntawm Huate Company, uas yog siv rau kev xaiv ua ntej ntawm cov hlau nplaum ua ntej sib tsoo lossis tsim cov khoom tsim nyog los ntawm cov hmoov magnetite.

Hmoov Ore Cua Qhuav Sib Nqus Separator

Txoj cai ua haujlwm

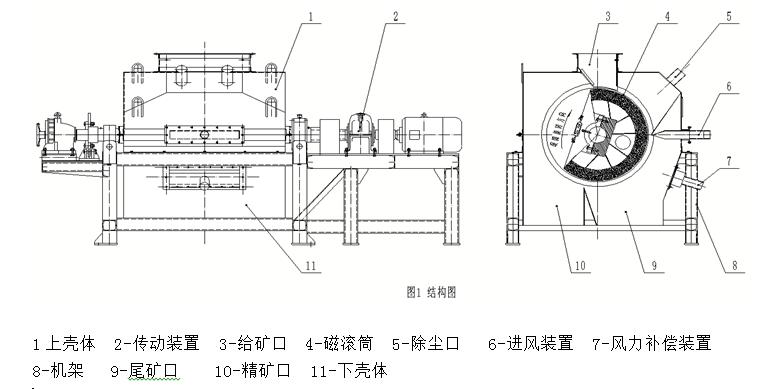

lub plhaub sab sauv 2. kis tau tus mob 3.Feed Qhov 4.Magnetic roller 5.dust qhov hluav taws xob 6.Air intake device 7.wind them nyiaj ntaus ntawv 8.frame 9.Tailings qhib 10.Concentrate qhib

qis plhaub

Lub hauv paus ntsiab lus ntawm kev ua haujlwm ntawm cov hmoov ore cua qhuav sib nqus sib nqus cais yog qhia hauv daim duab. Cov zaub mov yog pub rau saum npoo ntawm lub nruas hlau nplaum los ntawm qhov chaw nres nkoj ore noj 3, thiab cov khoom siv hlau nplaum yog adsorbed rau saum npoo ntawm lub nruas hlau nplaum 4 nyob rau hauv qhov kev txiav txim ntawm cov hlau nplaum, thiab tig nrog lub nruas sib nqus 4. Thaum lub sijhawm no txheej txheem, cov zaub mov nyob rau saum npoo ntawm lub nruas sib nqus 4 yog raug rau kev sib xyaw ua ke ntawm cov hlau nplaum sib nqus ntawm cov ntaub qhwv loj thiab ntau tus ncej sib nqus, cov khoom sib nqus sib nqus, cov khoom siv cua nkag 6 thiab qhov chaw nres nkoj tshem tawm plua plav. 5, kom cov impurities nyob rau hauv cov zaub mov thiab cov neeg pluag conjoined kab mob raug tshem tawm zoo. Li no, qib ntawm cov concentrate yog txhim kho. Tom qab cov pob zeb raug xaiv tau tig mus rau thaj chaw tsis sib nqus nrog lub nruas sib nqus 4, lawv tau ntxiv rau hauv qhov chaw nres nkoj concentrate 9 nyob rau hauv qhov kev txiav txim ntawm lub ntiajteb txawj nqus, lub zog centrifugal thiab unloading ntaus ntawv los ua concentrate. Cov hlau tsis muaj hlau nplaum lossis cov ntshiv sib txuas ntawm lub cev raug tshem tawm ntawm lub qhov ncauj 8 nyob rau hauv qhov kev txiav txim ntawm lub ntiajteb txawj nqus thiab lub zog centrifugal, thiab ua tailings los yog nruab nrab ore.

Kev tsim kho tshiab thiab thev naus laus zis tseem ceeb ntawm cov hmoov ore cua qhuav sib nqus sib nqus cais

1.Lub vibrating feeder yog siv rau kev pub mis, thiab cov tsis pub noj mov tuaj yeem hloov kho kom ua tiav kev noj zaub mov zoo ib yam;

2.The magnetic system txais ntau tus ncej, loj qhwv lub kaum sab xis (txog 200-260 degrees), lub zog siab (3000-6000Gs) tsim, thiab cov qauv sib nqus tuaj yeem hloov pauv raws li cov khoom ntxhia kom ua tiav cov txiaj ntsig tsim nyog ;

3.Lub linear ceev ntawm lub tog raj kheej yog kho nyob rau hauv 1-20m / s, thiab qhov tsim nyog linear ceev yuav raug xaiv raws li qhov xwm ntawm ore; lub tog raj kheej yog tsim los ntawm cov khoom siv tsis yog xim hlau thiab yog nruab nrog cov khoom sib nqus sib nqus kom txhim kho qib siab;

4.Nws muaj cov qauv dav hlau tshwj xeeb, cov cuab yeej siv hluav taws xob cua thiab cov khoom siv tshem tawm plua plav (tsim tsis muaj peev xwm xaiv tau raws li qhov xav tau ntawm cov ore); qhov saum npoo ntawm lub tog raj kheej yog muab nrog cov khoom siv thauj khoom, uas tuaj yeem paub qhov kev tawm huv huv ntawm cov concentrate;

FX hmoov ore huab cua qhuav sib nqus sib nqus sib cais yog tsim los ntawm cov khoom siv sib nqus, sib nqus sib nqus nruas, lub tshuab tshuab, lub tshuab nqus plua plav tshem tawm, cov khoom siv sedimentation, thiab lwm yam. Lub zog sib nqus ntawm lub nruas sib nqus sib nqus yog 3500Gs. . , sib nqus quab yuam, rotating centrifugal quab yuam, thiab lwm yam., tuaj yeem ua tiav qhuav ua ntej xaiv ntawm 0-5mm particle loj magnetite los yog zoo heev txhim kho qib zoo hmoov magnetite. Cov teebmeem tseem ceeb yog raws li nram no:

A. Cov qib xaiv ntawm 0-5mm magnetite tuaj yeem nce los ntawm 10% mus rau ntau tshaj 40%. Nws tuaj yeem siv ua ntej pov tseg ua ntej sib tsoo, uas tuaj yeem txhim kho qib nkag thiab txhim kho kev ua haujlwm ntawm lub zeb.

B.Qhov xaiv qib ntawm -74um thiab -45um nplua-grained magnetite tuaj yeem nce los ntawm 10% mus rau ntau dua 60%, thiab cov kev tsim nyog tau txais kev pom zoo tuaj yeem ncaj qha los ntawm kev xaiv qhuav.

Kev sim thiab kev soj ntsuam.

① Kev tshuaj xyuas cov ntsiab lus sib xws thiab tshawb xyuas cov khoom siv hlau.

② Kev npaj thiab ua kom huv ntawm cov zaub mov uas tsis yog xim hlau xws li lus Askiv, pob zeb ntev, fluorite, fluorite, kaolinite, bauxite, nplooj wax, baryrite, thiab lwm yam.

③ Cov txiaj ntsig ntawm cov hlau dub xws li hlau, titanium, manganese, chromium thiab vanadium.

④ Cov txiaj ntsig zoo ntawm cov hlau nplaum tsis muaj zog xws li dub tungsten ore, tantalum niobium ore, pomegranate, hluav taws xob roj, thiab huab cua dub.

⑤ Kev siv tag nrho ntawm cov peev txheej thib ob xws li ntau yam tailings thiab smelting slag.

⑥ Muaj cov ore-magnetic, hnyav thiab flotation ua ke cov txiaj ntsig ntawm cov hlau ferrous.

⑦ Kev txawj ntse sensing sorting ntawm metallic thiab non-metallic minerals.

⑧ Semi-industrialized nruam xaiv xeem.

⑨ Ultrafine hmoov ua xws li cov khoom crushing, pob milling thiab kev faib tawm.

⑩ EPC turnkey tej yaam num xws li crushing, pre-xaiv, sib tsoo, sib nqus (hnyav, flotation) sib cais, qhuav raft, thiab lwm yam.

Post lub sij hawm: Mar-14-2022