【01 Txheej txheem cej luam】

HUATE MAGNET

Tuam Tshoj cov khoom siv hlau ore yog nplua nuj nyob rau hauv reserves thiab ntau hom, tab sis muaj ntau yam lean ore, tsawg nplua nuj ore, thiab finely embedded grain loj. Muaj tsawg heev ore uas tuaj yeem siv ncaj qha, thiab ntau cov ore yuav tsum tau ua tiav los ntawm cov txiaj ntsig. Tau ntev, muaj ntau dua thiab nyuaj kev pab cuam nyob rau hauv cov ores xaiv, qhov beneficiation ratio tau loj thiab loj, cov txheej txheem thiab cov cuab yeej tau txais ntau thiab ntau nyuaj, tshwj xeeb tshaj yog cov nqi sib tsoo yog qhia ib tug zuj zus. Yog li ntawd, nws yog ib qho tseem ceeb heev kom txo tau lub zog noj ntawm cov txheej txheem sib tsoo nyob rau hauv cov txheej txheem beneficiation. Tam sim no, cov nroj tsuag hnav khaub ncaws feem ntau tau txais kev ntsuas xws li kev sib tsoo ntau dua thiab sib tsoo tsawg, kev xaiv ua ntej thiab muab pov tseg ua ntej sib tsoo, thiab lwm yam, uas tau ua tiav cov txiaj ntsig zoo kawg li.

Hauv cov cheeb tsam uas tsis muaj dej txaus, cov dej rau kev txhim kho mining tsis tuaj yeem lav tau, uas ua rau cov dej sib cais ntawm cov ntxhia ua tsis tau. Yog li ntawd, nyob rau hauv cov cheeb tsam no, lub qhuav pre-xaiv txoj kev yuav raug txiav txim siab ua ntej rau cov pov tseg pov tseg.

Qhov zoo crushing thiab qhuav polishing nrog ib tug particle loj ntawm 20-0 hli, thiab qhuav polishing ntawm crushed khoom ntawm high-pressure roller mills uas yog dav siv nyob rau hauv tam sim no, cov qauv ntawm cov khoom xaiv yog txawv. Lub tshuab nqus hlau sib nqus muaj cov yam ntxwv ntawm kev txuag qhov chaw teeb tsa, kev ua haujlwm loj, cov khoom seem siab thiab tus nqi rov qab siab, thiab tau ua tiav cov txiaj ntsig zoo hauv kev siv tswv yim.

[02 Lub hauv paus ntsiab lus thiab siv cov nyhuv]

HUATE MAGNET

Lub tshuab peb-nruas ua ke qhuav ua ntej xaiv tshuab feem ntau muaj ob qhov kev teeb tsa: ib qho roughing thiab ob cheb, thiab ib qho roughing thiab ob qho tag. Qhov sib nqus ncej layout qauv yog tsim raws li cov kev cai ntawm cov ntxhia sorting indicators, assumes tus nqi rejection thiab rov qab tus nqi, thiab los ntawm simulation tsom xam, ib-rau-ib tug tsim.

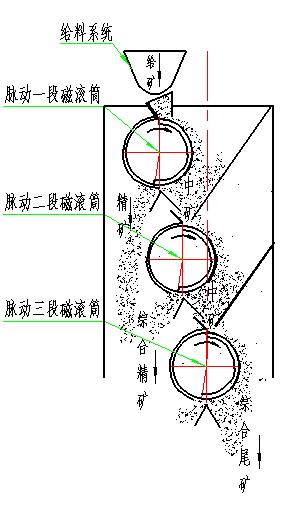

1. Lub hauv paus ntsiab lus ua haujlwm ntawm ib qho ntxhib thiab ob qhov cheb

Cov khoom siv nkag mus rau hauv cov ore los ntawm cov khoom noj. Cov ore yog sib cais los ntawm thawj lub nruas kom tshem tawm ib feem ntawm cov concentrate. Cov tailings ntawm thawj lub raj nkag mus rau lub raj thib ob rau cheb, cov tailings ntawm lub raj thib ob nkag mus rau hauv lub raj thib peb thiab cov tailings ntawm lub raj thib peb nkag mus rau lub raj thib peb. Rau qhov kawg tailings, cov concentrates ntawm thawj, thib ob thiab thib peb chim yog ua ke rau hauv qhov kawg concentrate. Lub hauv paus ntsiab lus ntawm kev ua haujlwm ntawm ib qho ntxhib ob scan yog qhia hauv daim duab 1.

▲ Daim duab 1 Schematic daim duab ntawm lub hauv paus ntsiab lus ua hauj lwm ntawm ib tug ntxhib thiab ob cheb

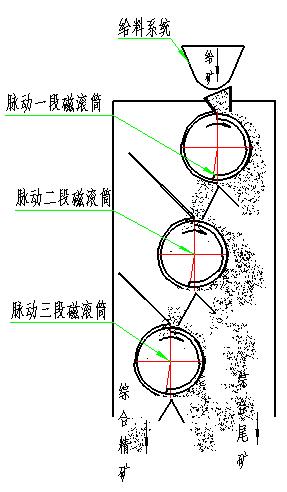

2. Lub hauv paus ntsiab lus ua haujlwm ntawm ib qho ntxhib thiab ob qhov zoo

Cov khoom siv nkag mus rau hauv cov ore los ntawm cov khoom noj. Tom qab cov ore sib cais los ntawm thawj lub nruas, cov concentrate nkag mus rau hauv lub thoob thib ob rau kev sib cais ntxiv, thiab cov concentrate nyob rau hauv lub thoob thib ob nkag mus rau hauv lub thoob thib peb rau kev sib cais. Lub concentrate nyob rau hauv lub thib peb chim yog qhov kawg concentrate. Cov tailings ntawm lub tog raj kheej thib ob thiab thib peb tau muab tso ua ke rau hauv qhov kawg tailings. Lub hauv paus ntsiab lus ua haujlwm ntawm ib qho ntxhib thiab ob qhov zoo yog qhia hauv daim duab 2.

▲ Daim duab 2 Schematic daim duab qhia kev ua haujlwm ntawm ib qho ntxhib thiab ob qhov zoo

3 .Application site ntawm MCTF series peb-nruas pulsating qhuav magnetic separator

▲ Daim duab 3 Daim ntawv thov chaw ntawm 3MCTF peb-nruas pulsating qhuav sib nqus sib nqus cais nrog cov menyuam pub khoom noj

Cov neeg siv khoom hauv daim duab saum toj no siv peb lub nruas 1030 qhuav ua ntej cais ntawm qhov chaw. Txoj kab uas hla ntawm lub nruas yog 1000mm thiab qhov ntev yog 3000mm. Cov txheej txheem txheej txheem yog ib qho roughing thiab ob cheb. Cov hlau nplaum hlau yog 0.6%, thiab cov seem seem yog ntau tshaj 30%, uas ua tiav cov txiaj ntsig xav tau.

【03 Chaw tsim khoom】

HUATE MAGNET

▲ Chaw tsim khoom ntawm peb-nruas pulsating qhuav magnetic separator

Scope ntawm kev pabcuam ntawm Huate Mineral Processing Engineering Design Institute

① Kev tshuaj xyuas cov ntsiab lus sib xws thiab tshawb xyuas cov khoom siv hlau.

② Kev npaj thiab ua kom huv ntawm cov zaub mov uas tsis yog xim hlau xws li lus Askiv, pob zeb ntev, fluorite, fluorite, kaolinite, bauxite, nplooj wax, thiab baryrite.

③ Cov txiaj ntsig ntawm cov hlau dub xws li hlau, titanium, manganese, chromium thiab vanadium.

④ Cov txiaj ntsig zoo ntawm cov hlau nplaum tsis muaj zog xws li dub tungsten ore, tantalum niobium ore, pomegranate, hluav taws xob roj, thiab huab cua dub.

⑤ Kev siv tag nrho ntawm cov peev txheej thib ob xws li ntau yam tailings thiab smelting slag.

⑥ Muaj cov ore-magnetic, hnyav thiab flotation ua ke cov txiaj ntsig ntawm cov hlau ferrous.

⑦ Kev txawj ntse sensing sorting ntawm metallic thiab non-metallic minerals.

⑧ Semi-industrialized nruam xaiv xeem.

⑨ Ultrafine hmoov ua xws li cov khoom crushing, pob milling thiab kev faib tawm.

⑩ EPC turnkey tej yaam num xws li crushing, pre-xaiv, sib tsoo, sib nqus (hnyav, flotation) sib cais, qhuav raft, thiab lwm yam.

Post lub sij hawm: Lub Xya hli ntuj-25-2022