Kaolin muaj ntau reserves nyob rau hauv kuv lub teb chaws, thiab cov pov thawj geological reserves yog hais txog 3 billion tons, feem ntau faib nyob rau hauv Guangdong, Guangxi, Jiangxi, Fujian, Jiangsu thiab lwm qhov chaw. Vim muaj qhov sib txawv geological tsim vim li cas, muaj pes tsawg leeg thiab cov qauv ntawm kaolin los ntawm ntau qhov chaw tsim khoom kuj txawv. Kaolin yog 1: 1 hom txheej silicate, uas yog tsim los ntawm octahedron thiab tetrahedron. Nws cov khoom tseem ceeb yog SiO2 thiab Al203. Nws kuj muaj ib qho me me ntawm Fe203, Ti02, MgO, CaO, K2O thiab Na2O, thiab lwm yam. Kaolin muaj ntau yam zoo ntawm lub cev thiab tshuaj thiab cov yam ntxwv ntawm cov txheej txheem, yog li nws yog dav siv nyob rau hauv petrochemicals, papermaking, functional material, coatings, ceramics, water-resistant material, etc. Nrog rau kev nce qib ntawm niaj hnub science thiab technology, siv tshiab kaolin. txuas ntxiv nthuav dav, thiab lawv tab tom pib nkag mus rau hauv qhov siab, meej thiab txiav-ntug teb. Kaolin ore muaj ib qho me me (feem ntau 0.5% mus rau 3%) ntawm cov hlau tsis muaj hlau (hlau oxides, ilmenite, siderite, pyrite, mica, tourmaline, thiab lwm yam), uas ua rau cov xim kaolin thiab cuam tshuam rau nws sintering Whiteness thiab lwm yam khoom txwv tsis pub siv. ntawm kaolin. Yog li ntawd, kev tsom xam ntawm cov kab ke ntawm kaolin thiab kev tshawb fawb ntawm nws cov tshuab tshem tawm impurity yog qhov tseem ceeb tshwj xeeb. Cov xim tsis huv no feem ntau muaj cov khoom sib nqus tsis muaj zog thiab tuaj yeem raug tshem tawm los ntawm kev sib nqus sib nqus. Sib nqus sib cais yog ib txoj kev ntawm kev sib cais cov ntxhia hauv cov hlau nplaum los ntawm kev siv cov hlau nplaum sib txawv ntawm cov ntxhia. Rau cov hlau nplaum uas tsis muaj zog, yuav tsum muaj cov hlau nplaum sib nqus zoo sib nqus.

Cov qauv thiab kev ua haujlwm ntawm HTDZ high gradient slurry magnetic separator

1.1 Cov qauv ntawm electromagnetic slurry high gradient magnetic separator

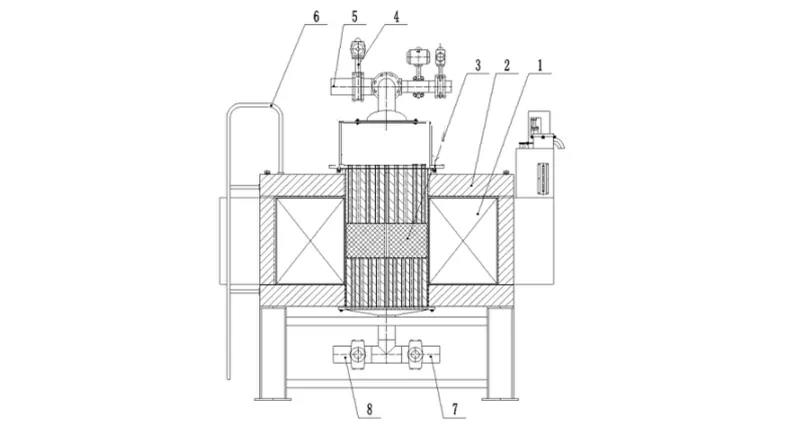

Lub tshuab yog tsim los ntawm thav duab, roj-txias excitation coil, sib nqus system, sib cais nruab nrab, coil txias system, flushing system, ore inlet thiab paug system, tswj system, thiab lwm yam.

Daim duab 1 Daim duab duab ntawm high gradient magnetic separator rau electromagnetic slurry

1- Excitation coil 2- Sib nqus system 3- Sib cais nruab nrab 4- Pneumatic valve 5- Pulp qhov hluav taws xob pipeline

6-Escalator 7-Inlet yeeb nkab 8-Slag tawm yeeb nkab

1.2 Cov yam ntxwv ntawm HTDZ electromagnetic slurry high gradient magnetic separator

◎Roj txias tshuab: Cov roj ntim ntim puv puv yog siv rau kev ua kom txias, kev sib pauv cua sov yog ua los ntawm kev siv lub hauv paus ntsiab lus ntawm cov roj-dej tshav kub pauv, thiab siv lub tshuab loj-flow disc transformer roj twj tso kua mis. Cov roj cua txias muaj qhov nrawm nrawm, muaj peev xwm hloov hluav taws xob muaj zog, qis coil kub nce, thiab siab sib nqus teb zog.

◎Tam sim no rectification thiab stabilization technology tam sim no: Los ntawm lub rectifier module, ruaj khov tam sim no tso zis, thiab lub excitation tam sim no raug kho raws li cov yam ntxwv ntawm cov khoom sib txawv los xyuas kom meej ruaj khov magnetic teb lub zog thiab ua tiav qhov zoo tshaj plaws beneficiation Performance index.

◎Loj kab noj hniav armored high-kev ua tau zoo lub cev hlau nplaum tshuab: Siv cov khoom siv hlau los qhwv lub hollow coil, tsim cov qauv tsim hluav taws xob sib nqus hlau nplaum, txo qhov saturation ntawm cov hlau armor, txo qhov sib nqus flux to, thiab ua kom muaj zog nyob rau hauv lub sorting kab noj hniav.

◎Khoom-kua-gas peb-theem sib cais tshuab: Cov khoom siv nyob rau hauv chav sib cais yog raug rau buoyancy, nws tus kheej lub ntiajteb txawj nqus, thiab sib nqus quab yuam kom ua tiav cov txiaj ntsig zoo raws li qhov tsim nyog. Kev sib xyaw ua ke ntawm cov dej ntws tawm thiab cov huab cua siab ua rau lub tshuab nqus dej nruab nrab.

◎Tshiab spiky stainless magnetic conductive thiab magnetic khoom technology: qhov nruab nrab sorting siv cov ntaub plaub hlau, pob zeb diamond zoo li xov xwm mesh, los yog kev sib xyaw ntawm cov ntaub plaub thiab pob zeb diamond-zoo li xov xwm mesh. Qhov nruab nrab no sib txuas cov yam ntxwv ntawm cov cuab yeej, thiab kev tshawb fawb thiab kev loj hlob ntawm hnav-resistant high-permeability stainless hlau, Lub magnetic teb induction gradient yog loj, nws yog yooj yim mus ntes tsis muaj zog magnetic minerals, lub remanence yog me me, thiab qhov nruab nrab yog yooj yim ntxuav thaum cov ore tawm.

1.3 Cov khoom siv hauv paus ntsiab lus tsom xam thiab kev txheeb xyuas cov khoom sib nqus

1.3.1Txoj cai sorting yog: Nyob rau hauv lub armored coil, ib tug npaum li cas ntawm magnetically conductive stainless hlau ntaub plaub (los yog nthuav hlau) yog muab tso rau. Tom qab lub coil zoo siab, cov hlau nplaum hlau tsis muaj hlau nplaum yog hlau nplaum, thiab cov hlau nplaum tsis sib luag yog tsim los ntawm qhov chaw, uas yog High-gradient magnetizing magnetic teb, thaum cov khoom siv paramagnetic hla dhau cov ntaub plaub hlau hauv lub tank sorting, nws yuav tau txais ib qho kev sib nqus quab yuam proportional rau cov khoom ntawm daim ntawv thov magnetic teb thiab cov magnetic teb gradient, thiab nws yuav tau adsorbed rau saum npoo ntawm cov ntaub plaub hlau, es tsis txhob ntawm cov khoom uas tsis yog-sib nqus mus rau magnetic teb ncaj qha. Nws ntws mus rau hauv lub tank uas tsis yog-magnetic khoom los ntawm cov tsis-magnetic valve thiab pipeline. Thaum cov khoom siv hlau nplaum tsis muaj zog uas tau sau los ntawm cov ntaub plaub hlau mus txog ib theem (txiav txim siab los ntawm cov txheej txheem yuav tsum tau ua), tso tseg tsis pub noj cov ore. Tshem tawm lub zog excitation thiab yaug cov khoom sib nqus. Cov khoom sib nqus ntws mus rau hauv cov khoom sib nqus tank los ntawm cov hlau nplaum thiab cov kav dej. Tom qab ntawd ua qhov homework thib ob, thiab rov ua lub voj voog no.

1.3.2Magnetic field distribution analysis: Siv cov software tshwj xeeb tshaj plaws kom simulate lub magnetic teb faib daim ntawv qhia huab cua, ua kom luv luv ntawm kev tsim thiab kev tsom xam; txais kev tsim kho kom zoo los txo cov khoom siv hluav taws xob thiab txo cov nqi siv; nrhiav pom cov teeb meem ua ntej cov khoom tsim, Ua kom muaj kev ntseeg siab ntawm cov khoom thiab cov haujlwm; simulate ntau yam kev xeem schemes, txo cov sij hawm xeem thiab cov nuj nqis;

Mineral txav yam ntxwv

2.1 Cov ntaub ntawv txav mus los

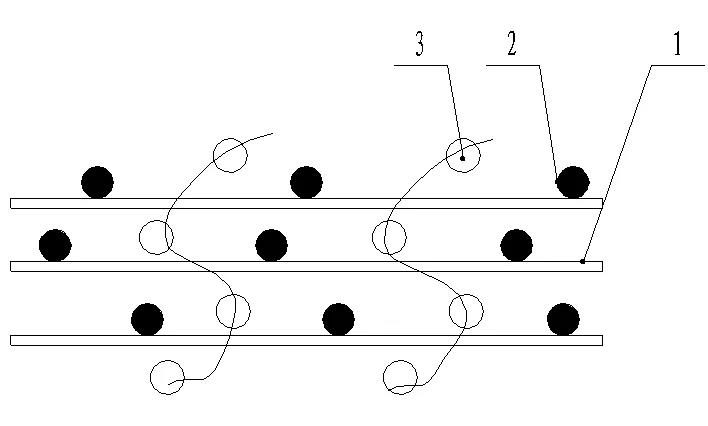

HTDZ high gradient sib nqus sib nqus cais yog tsim rau qis qis thaum muab kaolin. Cov cuab yeej siv ntau txheej stainless hlau wool (los yog nthuav dav hlau) raws li qhov nruab nrab sorting, thiaj li hais tias cov trajectory ntawm cov ore hais tsis xwm yeem nyob rau hauv txoj kab ntsug thiab kab rov tav. Qhov nkhaus txav ntawm cov pob zeb hauv av yog pom nyob rau hauv daim duab 1. Yog li ntawd, ncua sij hawm khiav thiab kev ncua deb ntawm cov pob zeb hauv qhov sib cais yog pab tau rau tag nrho cov adsorption ntawm cov hlau nplaum tsis muaj zog. Tsis tas li ntawd, cov slurry txaus tus nqi, lub ntiajteb txawj nqus thiab buoyancy thaum lub sij hawm sib cais txheej txheem sib cuam tshuam. Cov nyhuv yog ua kom cov ore hais nyob rau hauv ib lub xeev xoob txhua lub sij hawm, txo cov adhesion ntawm ore hais, thiab txhim kho cov efficiency ntawm hlau tshem tawm. Tau txais cov nyhuv sorting zoo.

Daim duab 4 Schematic daim duab ntawm ntxhia txav

1. Media network 2. Magnetic particles 3. Non-magnetic particles.

2. Qhov xwm ntawm cov ore raw thiab cov txheej txheem yooj yim ntawm cov txiaj ntsig

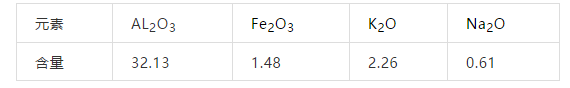

2.1 Cov khoom ntawm qee cov khoom siv hauv kaolin hauv Guangdong:

Gangue minerals ntawm kaolin nyob rau hauv ib cheeb tsam ntawm Guangdong muaj xws li quartz, muscovite, biotite thiab feldspar, thiab ib tug me me ntawm liab thiab limonite. Quartz feem ntau yog enriched nyob rau hauv lub + 0.057mm grain loj, cov ntsiab lus ntawm mica thiab feldspar minerals yog enriched nyob rau hauv nruab nrab grain loj (0.02-0.6mm), thiab cov ntsiab lus ntawm kaolinite thiab ib tug me me npaum li cas ntawm cov minerals tsaus maj mam nce raws li cov nplej. qhov loj me txo. , Kaolinite pib enriched ntawm -0.057mm, thiab yog obviously enriched ntawm -0.020mm loj.

Table 1 Kev txheeb xyuas ntau cov ntsiab lus ntawm kaolin ore%

2.2 Cov txiaj ntsig tseem ceeb muaj feem xyuam rau kev sim tshawb nrhiav cov qauv me me

Lub ntsiab yam tseem ceeb uas cuam tshuam rau cov txheej txheem sib nqus sib nqus ntawm HTDZ high gradient slurry magnetic separator yog cov slurry txaus tus nqi, lub keeb kwm yav dhau magnetic teb lub zog, thiab lwm yam. Ob lub ntsiab lus hauv qab no tau sim hauv qhov kev sim no.

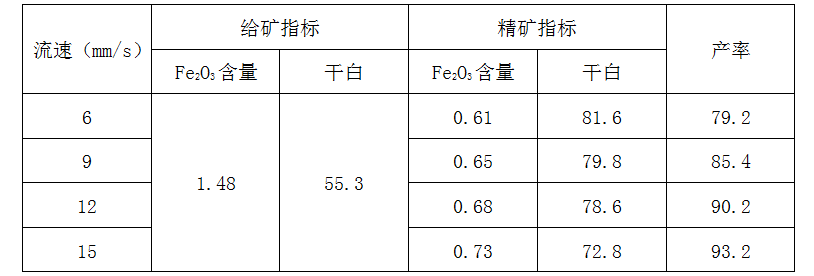

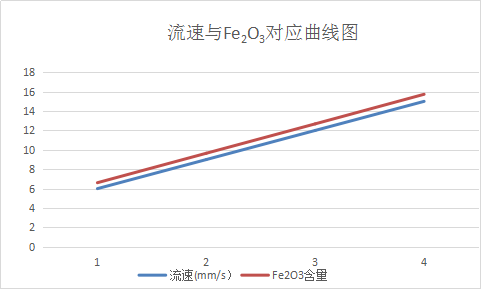

2.2.1 Slurry flow rate: Thaum tus nqi ntws loj, cov concentrate yield yog siab dua, thiab nws cov ntsiab lus hlau kuj siab; Thaum tus nqi ntws tsawg, cov ntsiab lus ntawm cov ntsiab lus hlau yog tsawg, thiab nws cov txiaj ntsig kuj tsawg. Cov ntaub ntawv sim tau qhia hauv Table 2

Table 2 Kev sim cov txiaj ntsig ntawm slurry flow rate

Lus Cim: Kev ntsuas slurry ntws yog ua raws li cov xwm txheej ntawm keeb kwm magnetic teb ntawm 1.25T thiab cov tshuaj dispersant ntawm 0.25%.

Daim duab 5 Kev sib tham ntawm tus nqi ntws thiab Fe2O3

Daim duab 6 Kev sib txuas lus ntawm kev khiav nrawm thiab qhuav dawb.

Xav txog cov txiaj ntsig tau txais txiaj ntsig zoo, cov slurry txaus tus nqi yuav tsum tau tswj ntawm 12mm / s.

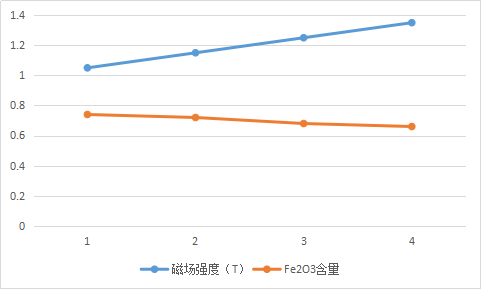

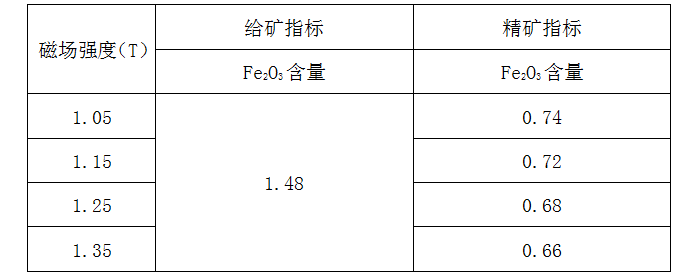

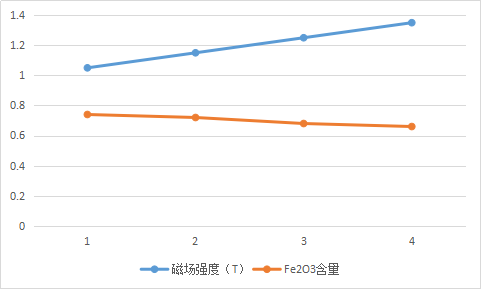

2.2.2 Background magnetic field: Lub keeb kwm yav dhau magnetic teb siv ntawm slurry magnetic separator yog raws li txoj cai ntawm cov hlau tshem tawm Performance index ntawm kaolin sib nqus sib cais, uas yog, thaum lub magnetic teb siv siab heev, lub concentrate yield thiab hlau ntsiab lus ntawm cov hlau nplaum sib nqus yog ob qho tib si qis, thiab cov hlau tshem tawm tus nqi kuj tsawg. Siab, muaj txiaj ntsig zoo ntawm kev tshem tawm cov hlau.

Table 3 Kev sim cov txiaj ntsig ntawm keeb kwm magnetic teb

Nco tseg: Kev kuaj keeb kwm yav dhau los yog ua raws li cov xwm txheej ntawm slurry txaus tus nqi ntawm 12mm / s thiab dispersant ntau npaum li cas ntawm 0.25%.

Vim tias qhov siab dua tom qab sib nqus qhov sib nqus, qhov ntau dua lub zog excitation, lub zog siv ntau dua ntawm cov khoom siv, thiab cov nqi tsim khoom ntau dua. Xav txog tus nqi ntawm cov txiaj ntsig, qhov kev xaiv keeb kwm yav dhau los sib nqus yog teem rau ntawm 1.25T.

Daim duab 7 Kev sib tham ntawm lub zog sib nqus thiab Fe2O3 cov ntsiab lus.

2.3 Cov txheej txheem yooj yim ntawm kev sib nqus sib nqus

Lub hom phiaj tseem ceeb ntawm kaolin ore tau txais txiaj ntsig yog tshem tawm cov hlau thiab ua kom huv. Raws li qhov sib nqus sib nqus ntawm txhua cov ntxhia, kev siv cov hlau nplaum sib nqus kom tshem tawm cov hlau thiab purify kaolin yog qhov zoo, thiab cov txheej txheem yog yooj yim thiab yooj yim rau kev siv hauv kev lag luam. Yog li ntawd, ib tug high-gradient slurry magnetic separator, ib co ntxhib thiab ib tug nplua, yog siv raws li cov txheej txheem sorting.

Muaj ntau lawm

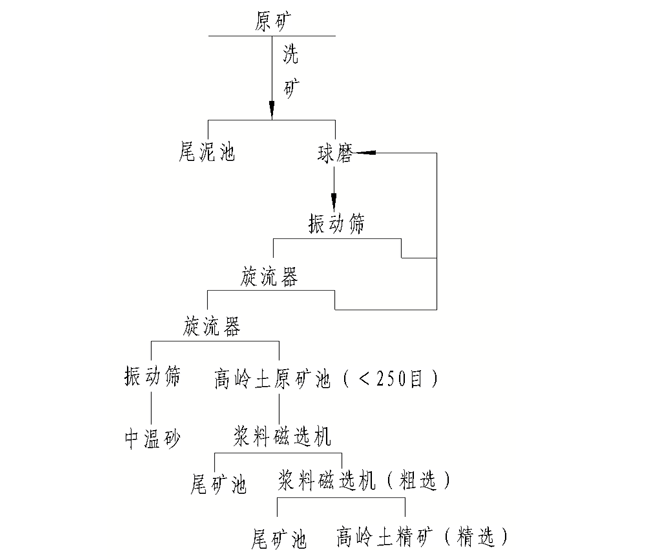

3.1 Kaolin industrial ntau lawm txheej txheem

Rau kev tshem tawm cov hlau los ntawm kaolin ore hauv ib cheeb tsam hauv Guangdong, HTDZ-1000 series ua ke yog siv los tsim cov txheej txheem sib nqus sib nqus sib nqus. Daim ntawv qhia ntws tau qhia hauv daim duab 2.

3.2 Muaj tej yam kev mob ntau lawm

3.2.1Kev faib cov khoom siv: lub hom phiaj tseem ceeb: 1. Sib cais impurities xws li quartz, feldspar thiab mica hauv kaolin ua ntej los ntawm ob-theem cua daj cua dub, txo qhov siab ntawm cov khoom siv tom ntej, thiab faib cov particle loj kom tau raws li cov khoom siv tom ntej. 2. Txij li qhov sib cais nruab nrab ntawm cov slurry sib nqus sib nqus sib nqus yog 3 # steel wool, qhov loj me me yuav tsum qis dua 250 mesh kom ntseeg tau tias tsis muaj cov khoom seem hauv cov ntaub plaub hlau nruab nrab los tiv thaiv cov ntaub plaub hlau nruab nrab los thaiv cov hlau ntaub plaub nruab nrab. , cuam tshuam cov txiaj ntsig Performance index thiab nruab nrab ntxuav Thiab kev ua haujlwm ntawm cov khoom siv, thiab lwm yam.

3.2.2Kev ua haujlwm ntawm kev sib nqus sib nqus: cov txheej txheem ntws tau txais ib qho ntxhib thiab ib qho kev sim zoo thiab ib qho ntxhib thiab ib qho zoo qhib Circuit Court txheej txheem. Raws li cov qauv kev sim, cov keeb kwm yav dhau lub zog ntawm high-gradient slurry magnetic separator rau roughing lag luam yog 0.7T, high-gradient sib nqus hlau nplaum rau kev xaiv ua haujlwm yog 1.25T, thiab HTDZ-1000 magnetic separator rau roughing slurry yog siv. . Nruab nrog HTDZ-1000 xaiv slurry magnetic separator.

3.3 Muaj cov txiaj ntsig kev tsim khoom

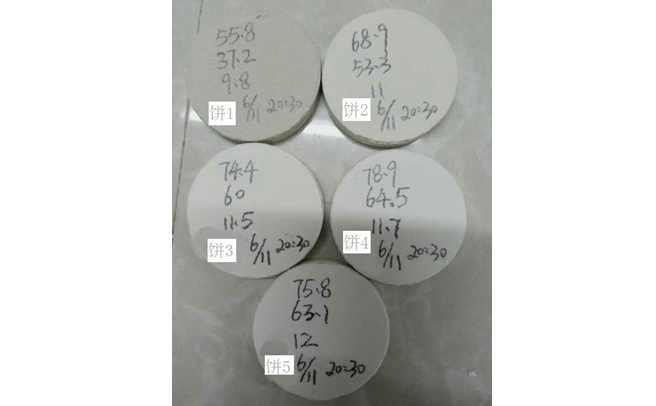

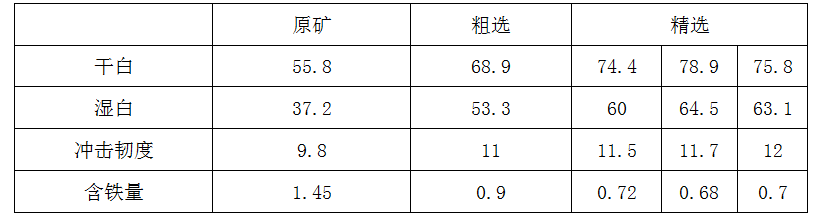

Kev lag luam ntawm kaolin rau hlau tshem tawm nyob rau hauv ib qho chaw hauv Guangdong, cov khoom lag luam qauv ncuav mog qab zib ua los ntawm HTDZ slurry high gradient sib nqus sib nqus cais yog qhia hauv daim duab 3, thiab cov ntaub ntawv tau qhia hauv Table 2.

Ncuav mog qab zib 1: Nws yog cov khoom nyoos ore qauv ncuav mog qab zib uas nkag mus rau qhov sib cais sib cais slurry sib nqus sib nqus

Pie 2: Roughly xaiv lub ncuav qab zib

Pie 3, Pie 4, Pie 5: Cov qauv xaiv

Table 2 Cov txiaj ntsig ntawm kev tsim khoom lag luam (cov txiaj ntsig ntawm kev kuaj thiab tawg ncuav ntawm 20: 30 ntawm Kaum Ib Hlis 6)

Daim duab 3 Ib qho piv txwv ncuav mog qab zib ua los ntawm kaolin nyob rau hauv ib qho chaw hauv Guangdong

Cov txiaj ntsig tau tshwm sim tau pom tias Fe2O3 cov ntsiab lus ntawm cov ntsiab lus tuaj yeem raug txo los ntawm 50% los ntawm ob qhov sib nqus sib nqus sib nqus ntawm cov slurry, thiab cov nyhuv tshem tawm hlau zoo tuaj yeem tau txais.

应用案例

Post lub sij hawm: Mar-27-2021