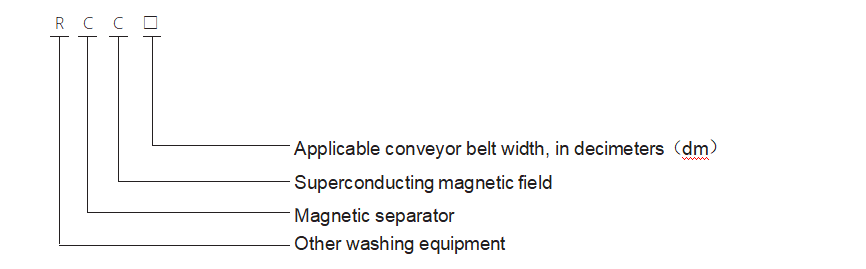

RCC Low Temperature Superconducting Sib Nqus Separator

Kev siv thiab nta

RCC low-temperature superconduct-ing magnetic separator siv cov hlau nplaum superconducting los ua kom muaj zog hlau nplaum uas xav tau rau kev tshem tawm hlau. Qhov kom zoo dua yog tias nyob rau hauv lub xeev superconducting (-268.8 ° C), muaj tam sim no tsis muaj kev tiv thaiv, thiab tam sim no dhau los ntawm superconducting coil los ua kom muaj zog magnetic teb. High magnetic teb lub zog, loj magnetic teb qhov tob, muaj zog hlau nqus muaj peev xwm, lub teeb yuag, tsis muaj zog noj, txuag hluav taws xob thiab kev tiv thaiv ib puag ncig, thiab lwm yam, qhov zoo uas zoo tib yam electromagnetic separators tsis phim. Nws yog tsuas yog siv los tshem tawm cov hlau impurities uas muaj nyob rau hauv lub coal seam.

Qauv piav qhia

Suav teb ua ntej qis kub superconducting hlau separator

Patent No: 200710116248.4

Kev ua tiav

Qhov kub-kub superconducting magnetic separator tau dhau lub xeev thiab kev tswj xyuas kev soj ntsuam thiab kev soj ntsuam cov khoom nyob rau lub Kaum Ib Hlis 2008 thiab Lub Rau Hli 2010 raws li, thiab tau txais peb patents hauv qab no:

◆ Ib qho kev tsim patent tau lees paub, lub npe patent yog "tsis tshua muaj kub superconducting muaj zog

Sib nqus separator” (ZL200710116248.4)

◆ Ib qho qauv siv hluav taws xob tau lees paub, thiab lub npe patent yog "Superconducting Magnetic Separator Suspension Device" (ZL 2007 2 0159191.1)

◆ Ib qho qauv siv hluav taws xob tau lees paub, thiab lub npe patent yog "Kev tiv thaiv yooj yim rau hauv qab phaj ntawm superconducting Sib Nqus Separator". (ZL 200820023792.4)

Khoom siv

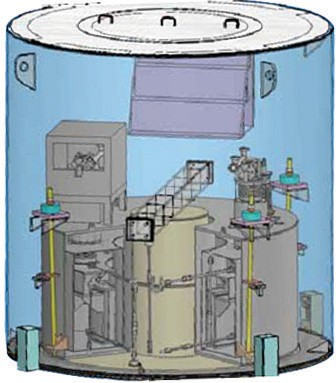

Qhov kub-kub superconducting magnetic separator feem ntau yog tsim los ntawm lub plhaub thiab cov khoom dai, cov khoom siv hlau nplaum superconducting, lub tub yees thiab lub tshuab tsis siv neeg tswj. Cov hlau nplaum superconducting yog dai rau ntawm lub plhaub, thiab lub tub yees system yog siv los tswj qhov kub ntawm cov kua helium.

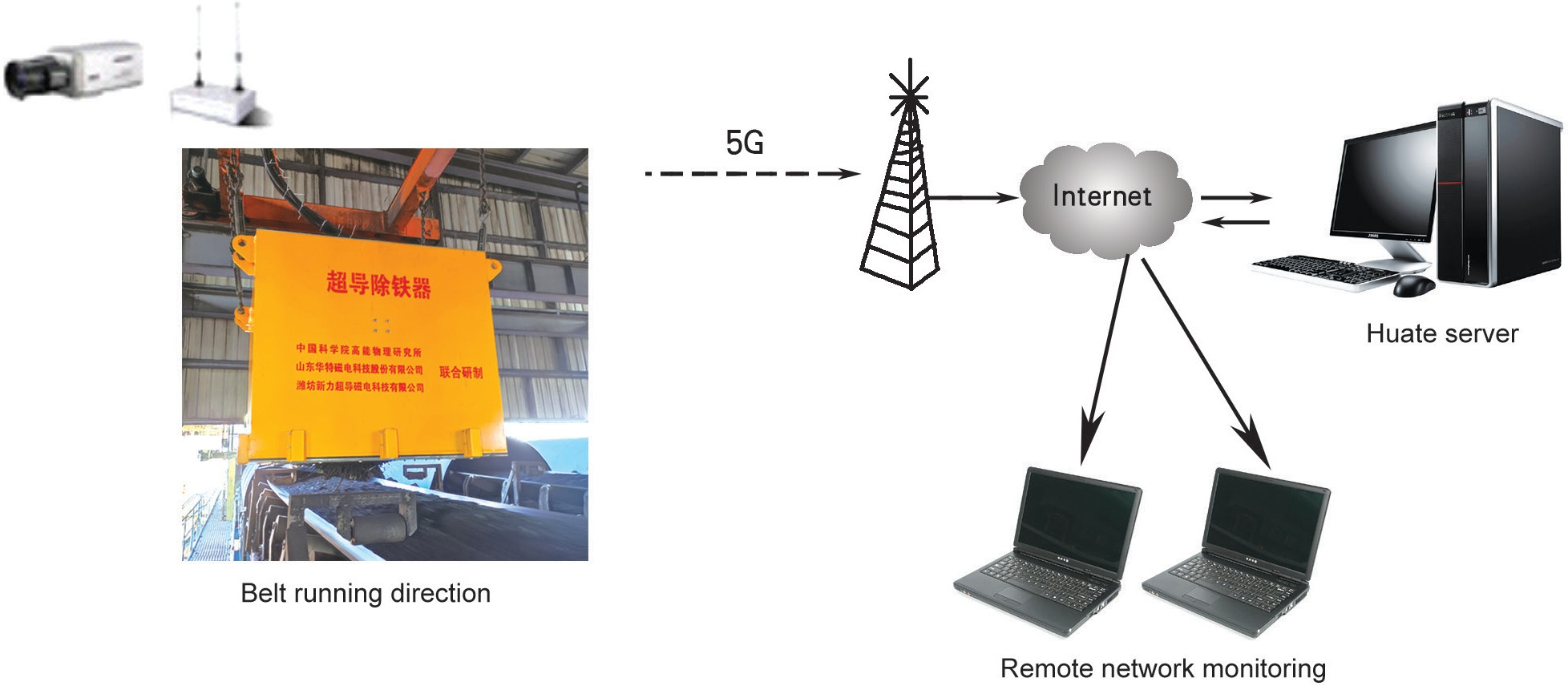

Lub kaw lus tswj tsis siv neeg tuaj yeem paub txog kev tswj chaw taws teeb thiab kev kuaj xyuas cov chaw taws teeb ntawm wireless network. Cov duab hauv qab no yog daim duab peb sab schematic thiab cov duab ua haujlwm ntawm qhov kub thiab txias superconducting magnetic separator.

Schematic daim duab

Tsis siv neeg tswj thiab saib xyuas tej thaj chaw deb

Qhov kub tsis tshua muaj superconducting magnetic separator ntawm txoj hauj lwm ntawm absorbing hlau

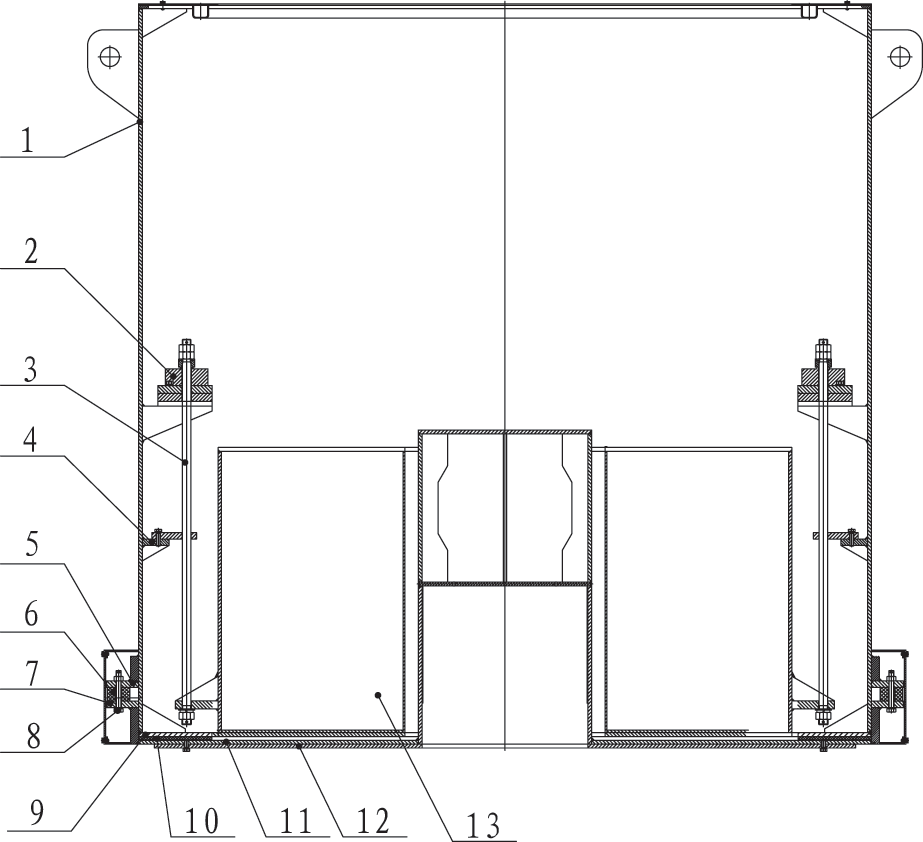

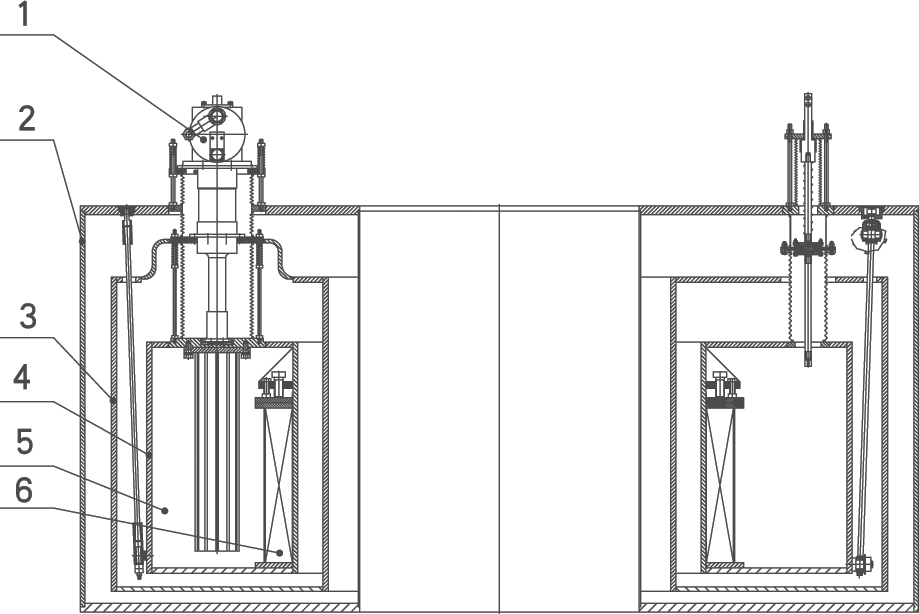

Cov duab hauv qab no yog daim duab schematic ntawm lub plhaub thiab cov cuab yeej dai ntawm qhov kub thiab txias su-perconducting magnetic separator

1.qo cev

2. Pressure Sensor

3. Cov pas nrig

4. positioning bracket

5. Kho phaj

6.elastomer

7.movable board

8. txuas ntsia liaj qhov rooj

9. Plhaub hauv qab phaj

10.flexible roj hmab

11. txuas phaj

12.High-manganese hauv qab phaj

13. hlau nplaum

◆ Cov hlau nplaum 13 ntawm lub superconducting magnetic separator yog tsau rau ntawm lub plhaub 1 los ntawm Hanging rod 3, thiab sab sauv ntawm Hanging rod 3 yog nruab nrog lub siab sensor 2 txhawm rau txheeb xyuas lub zog ntawm superconducting magnetic separator txhua lub sijhawm.

Thaum lub superconducting magnetic separator ua hauj lwm, lub tramp hlau cuam tshuam rau lub siab-manganese hauv qab phaj 12 ntawm lub plhaub ntawm kev kub ceev, ua kom siab ntawm cov phaj txuas 11. Lub sijhawm no, lub elastomer 6 yog compressed thiab deformed los ntawm cov phaj txuas. 11 kom nqus tau qhov cuam tshuam lub zog. Thaum muaj kev cuam tshuam loj, Thaum lub elastomer 6 yog compressed rau ib qho twg, cov roj hmab hloov tau 10 yog compressed los tsim deformation thiab nqus lub zog cuam tshuam, zoo xyuas kom meej tias lub plhaub 1 tsis vibrate thaum lub superconducting hlau tshem tawm ua haujlwm, yog li xyuas kom meej tias cov hlau nplaum superconducting tshem tawm ntawm lub plhaub 1 lub hlau nplaum 13 ua haujlwm ruaj khov.

Txoj Cai Ua Haujlwm

◆ Daim duab hauv qab no yog daim duab schematic ntawm cov qauv ntawm cov hlau nplaum superconducting. Lub coil 6 yog immersed nyob rau hauv cov kua helium 5. Cov kua helium muab superconducting uas tsis tshua muaj kub 4.2K thaum lub superconducting coil ua haujlwm. Cov kua helium 5 yog encapsulated nyob rau hauv lub tshuab nqus tsev siab 4K Dewar 4. , Yuav kom ntseeg tau qhov qis tshaj kub to ntawm qhov qis-kub Dewar, uas yog, 4K Dewar, 40K tshav kub daim thaiv 3 thiab 300K Dewar 2 yog ntsia sab nraum. nws los xyuas kom meej tias lub kaw lus nce mus txog qhov sib npaug ntawm thermal, kom lub superconducting hlau tshem tawm tuaj yeem ua haujlwm ruaj khov thiab ruaj khov. Tus naj npawb 1 yog lub tub yees.

1. tub yees

2. Dewar

3. tshav kub ntaub thaiv npog

4.4K Dewar

5.liquid helium 6.superconducting coil

◆ Vim muaj qhov sib nqus sib nqus siab heev uas tsim los ntawm qhov kub thiab txias superconducting magnetic separator, lub zog sib nqus loj loj yuav ua rau cov khib nyiab hlau cuam tshuam rau cov hlau nplaum ntawm qhov ceev ceev, uas yuav ua rau muaj kev puas tsuaj rau cov hlau nplaum superconducting. Yog li ntawd, cov hlau nplaum superconducting ntawm qhov kub-kub superconducting sib nqus sib nqus cais yog raug tshem tawm ntawm lub plhaub los ntawm Suspension Device. Lub plhaub yog nruab nrog lub teb chaws patented khoom - ib tug saj zawg zog dai de-vice. Thaum cov khib nyiab hlau cuam tshuam rau cov hlau nplaum, cov cuab yeej no tuaj yeem tso siab rau lub zog cuam tshuam, tiv thaiv cov hlau nplaum superconducting los ntawm kev puas tsuaj, thiab xyuas kom meej tias qhov kub thiab txias superconducting magnetic separator tuaj yeem ua haujlwm tau ntev.

◆ Lub lag luam tswj ib feem ntawm qhov kub-kub superconducting sib nqus sib nqus sib nqus tau txais Chi-nese thiab lus Askiv ua haujlwm sib cuam tshuam, uas yooj yim rau kev nkag siab, siv tau yooj yim, tswj tau yooj yim, thiab tuaj yeem paub txog kev sib kis hauv online ntawm cov ntaub ntawv kev ua haujlwm thiab kev saib xyuas online ntawm kev ua haujlwm. , paub txog cov chaw taws teeb tswj thiab kuaj mob, txhim kho kev ntseeg siab ntawm cov khoom siv ua haujlwm.

Qhov zoo

◆ Tus nqi qis

1) Lub superconducting hlau nplaum ntawm superconducting magnetic separator txais lub tshuab nqus tsev roj impregnation technology, uas ua rau lub sij hawm luv luv thiab txo cov nqi tsim khoom.

2) Txais cov kua helium immersion txias, tsis zoo siab ua haujlwm, xoom volatilization, txuag tus nqi ntawm cov kua helium, thiab txhim kho kev ruaj ntseg ntawm cov hlau nplaum ua haujlwm.

3) Lub teeb yuag, tag nrho loj txog 8 tons, yooj yim rau nruab.

◆ Tsawg khiav lag luam thiab tu nqi

1) Lub taub hau txias yog yooj yim los tuav. Lwm lub tuam txhab cov khoom yuav tsum tau ua kom sov sov rau lub taub hau txias, uas yuav siv li 15 hnub; thaum peb lub tuam txhab cov khoom tuaj yeem hloov pauv lub taub hau txias hauv lub xeev txias, thiab lub sijhawm hloov tsuas yog 1 teev, uas tuaj yeem txuag tau sijhawm, pab txhawb kev sib cais ntawm cov hlau txuas ntxiv thiab txhim kho kev tsim khoom.

2) Tsawg poob ntawm cov kua helium thaum hloov lub taub hau txias. Hloov lub taub hau txias rau lwm lub tuam txhab cov khoom yuav tsum rov ua kom sov. Tom qab tag nrho cov kua helium hauv cov hlau nplaum volatilizes, hloov lub taub hau txias, thiab tom qab ntawd muab cov kua helium rov ua haujlwm ib txwm;

Txawm li cas los xij, peb cov khoom tuaj yeem hloov pauv hauv lub xeev txias, tsuas yog me me ntawm cov kua helium volatilizes,

thiab tuaj yeem ua haujlwm ib txwm tsis muaj cov kua helium ntxiv.

3) cov nqi kho mob tsawg

◆ Yooj yim rau kev khiav lag luam. Nws txais yuav Suav thiab Askiv interface, desktop computer tswj lossis kov screen computer tswj, uas yooj yim rau kev nkag siab thiab ua haujlwm.

◆ Kev saib xyuas tej thaj chaw deb. Ntau lub koob yees duab tau teeb tsa rau ntawm qhov chaw los saib xyuas cov xwm txheej ntawm kev ua haujlwm ntawm cov khoom sib nqus sib nqus, thiab kev ua haujlwm ntawm qhov chaw sib nqus sib nqus tuaj yeem saib xyuas los ntawm lub network. Nws cov kev khiav hauj lwm tsis yog kis mus rau cov chaw taws teeb davhlau ya nyob twg los ntawm lub network. Los ntawm kev txheeb xyuas qhov kev ua haujlwm tsis zoo, cov kws tshaj lij tuaj yeem tshawb pom cov teeb meem tshwm sim ntawm lub tshuab hluav taws xob sib nqus sib nqus ua ntej, thiab coj cov neeg ua haujlwm ntawm qhov chaw los daws lawv ua ntej lossis npaj ua ntej los txo qhov tshwm sim ntawm qhov ua tsis tiav.

◆ Lub sij hawm excitation thiab demagnetization yog luv. Lub sij hawm magnetization yog 25 feeb thiab lub sij hawm de magnetization yog 20 feeb.

◆ Muaj peev xwm nyiam cov hlau. Qhov hnyav tshaj plaws ntawm ib daim hlau uas tuaj yeem nyiam yog txog 8 kg, thiab qhov siab tshaj plaws ntawm cov hlau nyiam hauv ib zaug tuaj yeem ncav cuag 35 kg.

◆ Cov khoom muaj kev ruaj ntseg siab. Segmented kev tiv thaiv kev ntsuas tau txais los ua kom tiav lub zog tsis sib xws, txo cov hluav taws xob hauv cov hlau nplaum, thiab tiv thaiv cov hlau nplaum zoo; Kev ua haujlwm tsis zoo yog raug siv los txhim kho kev ua haujlwm ruaj khov ntawm cov hlau nplaum.

Technical parameters

| Conveyor siv dav mm | 1600 | 1800 | 2000 | 2200 | 2400 |

| Suspension qhov siab mm | 500 | 500 | 550 | 550 | 550 |

| Sib nqus sib nqus ≥ mT | 400 | ||||

| Sib nqus teb siv nyob rau hauv qab ntawm lub plhaub ≥mT | 2000 | ||||

| Kev siv lub tshuab fais fab ≤KW | 30 | ||||

| Ua haujlwm system | Online hlau sib cais-offline hlau unloading-online hlau sib cais | ||||

| Qhov loj me mm | 1500 × 1500 hli | 1700 × 1700 hli | 1900 × 1900 hli | 2100 × 2100 hli | 2300 × 2300 hli |

| Nyhav kg | 6700 ib | 7200 ib | 8000 | 9500 ua | 11 000 |

(Rau siv xwb)

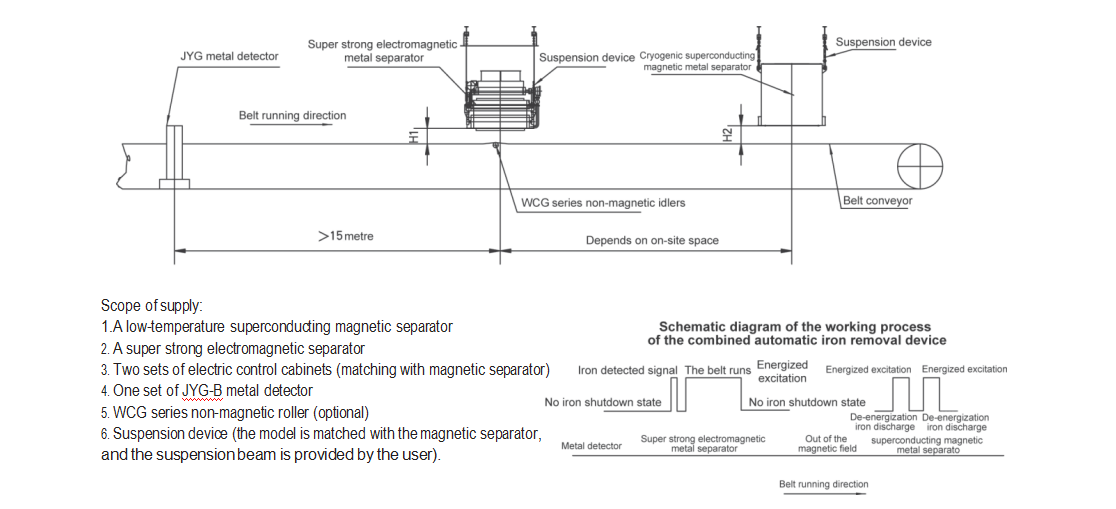

Ua ke tsis siv neeg hlau sib cais ntaus ntawv

Cov cuab yeej siv qhov chaw