IB TUG NTAU TSHAJ PLAWS NYIAJ ROV LOS

Daim Ntawv Thov Scope

Ib leeg-tsav siab siab sib tsoo yob yog tshwj xeeb tsim los ua ntej sib tsoo cov cement clinkers, cov ntxhia pob zeb, cov hlau clinkers thiab lwm yam rau hauv cov granules me me, txhawm rau txhawm rau ultra-tshem cov khoom siv hlau (hlau ores, manga-nese ores, tooj liab ores. , lead-zinc ores, vanadium ores thiab lwm yam) thiab zom cov zaub mov uas tsis yog xim hlau (cov thee gangues,

feldspar, nephe-line, dolomite, limestone, quartz, thiab lwm yam) rau hauv hmoov.

Qauv & Txoj Cai Ua Haujlwm

◆ Daim duab qhia ua haujlwm

Lub singledrive siab sib tsoo yob adopts

txoj cai sib tsoo ntawm cov khoom sib sau ua ke extrusion.

Ib qho yog yob nyob ruaj ruaj thiab lwm qhov yog txav tau yob.

Ob lub rolls tig oppositely ntawm tib lub ceev.

Cov khoom siv nkag los ntawm qhov qhib qhib sab saud,

thiab yog grinded vim extrusion los ntawm kev kub siab nyob rau hauv qhov sib txawv ntawm ob yob, thiab tawm los ntawm hauv qab.

◆ Tsav ib feem

Tsuas yog ib lub cev muaj zog tsav yog xav tau,

lub zog yog kis los ntawm qhov chaw nres tsheb mus rau qhov txav txav tau los ntawm lub iav system,

yog li ntawd ob lub yob yog synchronized tag nrho tsis muaj zawv zawg kev sib txhuam.

Kev ua haujlwm yog txhua yam siv rau cov khoom siv extrusion,

thiab kev siv hluav taws xob siv hluav taws xob yog qhov siab, uas txuag tau 45% ntawm hluav taws xob piv rau cov pa hluav taws xob siab sib tsoo yob.

◆ Kev siv lub zog

Lub caij nplooj ntoos hlav sib xyaw ua haujlwm siab siv qhov system ua rau cov yob txav txav kom tsis txhob yoog raws.

Thaum muaj hlau txawv teb chaws nkag mus,

Lub caij nplooj ntoos hlav siab siv qhov system ncaj qha rov qab thiab ua rau lub sijhawm, kom ntseeg tau tias qhov kev ua haujlwm siab li 95%;

thaum cov tsoos siab sib tsoo yob ua kom tsis txhob, cov roj hydraulic yuav tsum tau tso tawm los ntawm cov raj xa dej kom txo tau qhov siab.

Qhov kev txiav txim yog ncua, uas yuav ua rau muaj kev puas tsuaj rau lub yob nto los yog malfunction ntawm hydraulic system.

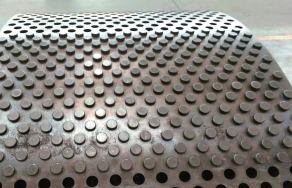

◆ Yob nto

Lub yob nto yog surfacing welded nrog alloy hnav-resistant vuam khoom, thiab lub hardness yuav ncav cuag HRC58-65; lub siab tau hloov kho nrog cov khoom siv,

uas tsis tsuas yog ua tiav lub hom phiaj ntawm kev sib tsoo, tab sis kuj tiv thaiv cov yob nto;

lub movable yob thiab cov yob nyob ruaj ruaj ua haujlwm synchronously yam tsis muaj kev sib txhuam.

Yog li ntawd, qhov kev pab cuam lub neej ntawm yob nto yog ntau dua li cov pa siab sib tsoo yob.

Main Technical nta

◆ Kev ua haujlwm siab. Piv nrog rau cov khoom siv tsoos tsoos, kev ua haujlwm muaj peev xwm nce 40 - 50%.

Lub peev xwm ua haujlwm rau PGM1040 tuaj yeem ncav cuag 50 - 100 t / h, tsuas yog 90kw zog.

◆ Kev siv hluav taws xob tsawg. Raws li txoj kev tsav tsheb ib leeg, nws xav tau tsuas yog ib lub cav tsav.

Kev siv hluav taws xob tsawg heev. Piv nrog rau cov tsoos tsav ob zaug HPGR, nws tuaj yeem txo qhov kev siv hluav taws xob los ntawm 20 ~ 30%.

◆ Zoo hnav-tiv taus zoo. Nrog tsuas yog ib lub cev muaj zog tsav tsheb, kev ua haujlwm synchronization ntawm ob lub yob yog qhov zoo heev.

Nrog rau qhov hnav-tiv taus vuam qhov chaw, cov yob yog nrog zoo hnav-tiv taus zoo thiab tuaj yeem tswj tau yooj yim.

◆ Kev ua haujlwm siab: ≥ 95%. Nrog rau kev tsim qauv tsim, cov cuab yeej tuaj yeem raug nias los ntawm cov pab pawg siab siab caij nplooj ntoos hlav.

Kev ua haujlwm siab tuaj yeem hloov kho tau raws li cov pab pawg caij nplooj ntoos hlav compress. Tsis muaj qhov ua haujlwm tsis zoo.

◆ High Automation thiab hloov tau yooj yim. Yog tsis muaj lub hydraulic system, muaj tsawg malfunction tus nqi

◆ Lub yob nto yog surfacing welded nrog alloy hnav-resistant welding khoom, nrog siab hardness thiab zoo hnav tsis kam;

Lub siab rau lub caij nplooj ntoos hlav los ntawm cov tshuaj tiv thaiv quab yuam ntawm cov khoom, thiab lub siab yog ib txwm sib npaug,

uas tsis tsuas yog ua tiav lub hom phiaj ntawm crushing,

tab sis kuj tiv thaiv cov yob nto; lub movable yob thiab cov yob nyob ruaj ruaj yog meshed thiab tsav los ntawm lub iav system,

thiab qhov ceev yog synchronized kiag li, yog li tsis txhob zawv zawg kev sib txhuam ntawm cov khoom thiab yob nto.

Yog li ntawd, lub neej kev pab cuam ntau dua li ntawm ob lub tsav HPGR .

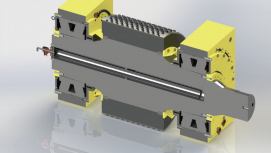

◆ Compact qauv thiab me me hauv pem teb chaw.

Technical Parameters

| Qauv | Roll txoj kab uas hlamm | Yobdav mm | M ax .feedsize(Cement, steel slag, oreslag) mm | Zoo pubqhov loj(hlaum i n e r a l,non-metallicntxhia) mm | mmOutput loj(cement)mm | Kev ua tau zooT/h | M o t o rzog kw | Qhia qhov ntev(L × W × H)mm |

| pwm 0850 | φ800 | 500 | 50 | 30 | Kev faib tawm, <4 | 30~40 | 37 | 2760 × 2465 × 1362 hli |

| PWM 1040 | φ1000 | 400 | 50 | 30 | Kev faib tawm, <4 | 50~80 | 90 | 4685 × 4300 × 2020 |

| PWM 1060 | φ1000 | 600 | 50 | 30 | Kev faib tawm, <4 | 70~110 | 110 | 4685 × 4300 × 2020 |

| PWM 1065 | φ1000 | 650 | 50 | 30 | lassifying, <4 | 100~160 | 200 | 5560 × 4500 × 2200 hli |

| PWM 1250 | φ1200 | 500 | 50 | 30 | Kev faib tawm, <4 | 120~180 | 250 | 6485 × 4700 × 2485 hli |

| PWM 1465 | φ1400 | 650 | 50 | 30 | Kev faib tawm, <4 | 240~320 | 630 | 9200 × 6320 × 3600 hli |

| PWM 1610 | φ1600 Nws | 1000 | 50 | 30 | Kev faib tawm, <4 | 500~650 | 1250 | 10800 × 8100 × 4400 hli |

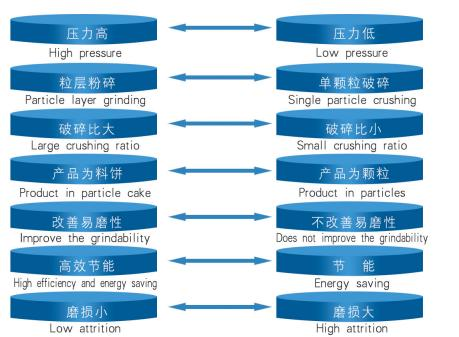

Kev sib piv ntawm ib leeg DRIVE HPGR thiab CONVENTIONAL HPGR

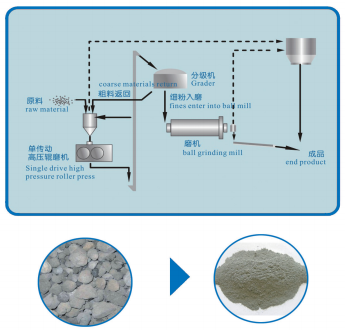

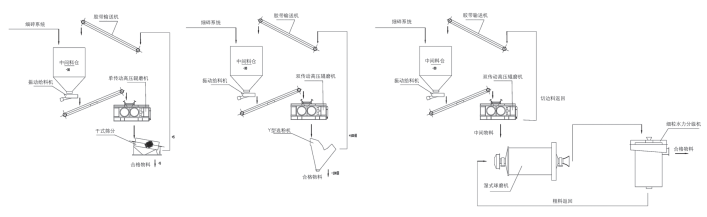

PRE-GRINDING PROCESS FLOW chart of single DRIVE HPGR

Kev sib tsoo ua ntej ntawm cov cement, ore slag thiab steel slag "Ntau crushing thiab tsawg sib tsoo, hloov kev sib tsoo nrog crushing", uas yog, pre-sib tsoo, tau dhau los ua cov thev naus laus zis thev naus laus zis rau cov yeeb nkab zeb cov txheej txheem los ua kom ntau lawm thiab txo kev siv hluav taws xob. . Raws li cov cuab yeej zoo tshaj plaws ua ntej sib tsoo lub zog txuag, ib leeg-tsav HPGR tuaj yeem tsoo cov ntaub ntawv mus rau -4mm lossis -0 .5mm, ntawm 0 .08mm suav nyiaj ntau dua 30%. Lub peev xwm ntawm kev siv pob zeb tuaj yeem nce los ntawm 50 ~ 100%, thiab kev sib tsoo lub zog siv tau tuaj yeem txo los ntawm 15 ~ 30%.

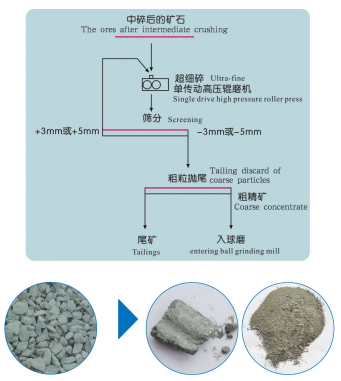

ULTRA FINE CRUSHING PROCESS FLOW chart of metallic mineral with single DRIVE HPGR

Ultra Fine Crushing ntawm Metallic Mineral

Thaum cov pob zeb hauv av dhau los ntawm qhov sib txawv ntawm ob lub yob, lawv raug crushed rau hauv cov khoom zoo ntawm -5 hli lossis -3 hli thiab ntau cov hmoov los ntawm kev kub siab. Vim lub zog tsis muaj zog ntawm kev sib txuas ntawm cov pob zeb muaj txiaj ntsig thiab cov gangue, qaug zog tawg lossis micro-kawg thiab kev ntxhov siab sab hauv tau yooj yim tsim. Ib feem ntawm lub interface yuav dissociated kiag li.

Vim tias cov ntsiab lus siab ntawm cov hmoov zoo tawm los ntawm HPGR thiab qhov tseeb tias cov pob zeb hauv av tau crushed raws qhov chaw sib cais, piv nrog cov kev sib tsoo, qhov kev faib ua feem ntawm kev sib tshuam hauv cov khoom crushed yog txo, thiab tailing pov tseg. fect yog zoo.

Ob qhov coarse concentrate qib thiab cov pov tseg pov tseg tawm los tau zoo heev.

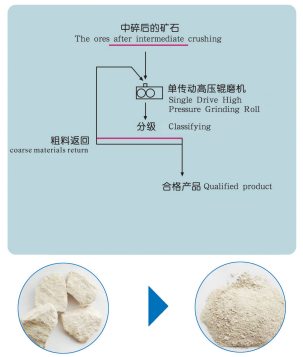

APPLICATION PROCESS FLOW chart FOR non-metallic mineral with single DRIVE HPGR

Non-Metallic Mineral Sib Tsoo

Piv nrog rau cov khoom sib tsoo tsoos, ib leeg-tsav HPGR muaj qhov zoo ntawm lub tshuab loj ib leeg, kev siv hluav taws xob tsawg, hnav tsawg dua thiab muaj kuab paug tsawg; cov khoom zoo tuaj yeem tswj tau los ntawm 20 mesh mus rau 120 mesh, uas tuaj yeem hloov pob zeb thiab tsim cov txheej txheem sib tsoo tshiab.

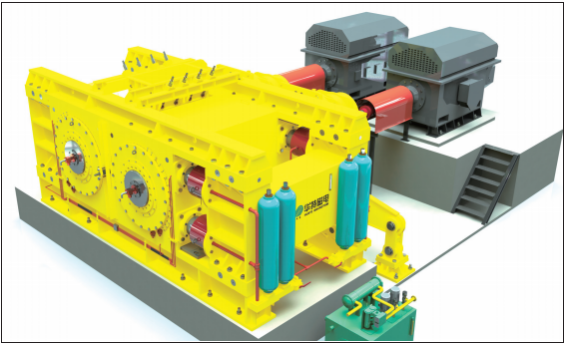

HPGM SERIES HIGH Pressure GRINDING ROLL

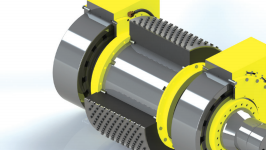

Txoj Cai Ua Haujlwm

HPGM series siab sib tsoo yob yog ib yam tshiab ntawm lub zog txuag kev sib tsoo khoom tsim los ntawm lub hauv paus ntsiab lus ntawm high-pressure khoom txheej pulverization. Nws muaj ob lub squeezing yob uas tig synchronously ntawm ib tug tsawg ceev. Ib qho yog ib qho yob nyob ruaj ruaj thiab lwm qhov yog lub yob txav tau, uas yog ob qho tib si uas tau tsav los ntawm lub cev muaj zog. Cov ntaub ntawv yog sib npaug los ntawm saum toj no ob lub yob, thiab txuas ntxiv nqa mus rau hauv qhov sib txawv ntawm qhov sib tov los ntawm kev nyem yob. Tom qab raug kev kub ntxhov ntawm 50-300 MPa, lub ncuav mog qab zib tuab yog tawm ntawm lub tshuab. Nyob rau hauv lub ncuav mog qab zib cov khoom tawm, ntxiv rau ib qho kev faib ua feem ntawm cov khoom tsim nyog, cov qauv sab hauv ntawm cov khoom tsis tsim nyog tau ntim nrog ntau cov kab nrib pleb vim kev kub siab extrusion, yog li cov khoom muaj peev xwm zom tau. kho tau zoo heev. Rau cov ntaub ntawv tom qab extrusion, tom qab kev tawg, kev faib tawm thiab kev tshuaj ntsuam, cov ntaub ntawv zoo ntawm tsawg dua 0.8 hli tuaj yeem ncav cuag li 30%, thiab cov ntaub ntawv tsawg dua 5 hli tuaj yeem ncav cuag ntau dua 80%. Yog li ntawd, nyob rau hauv cov txheej txheem sib tsoo ntxiv, kev sib tsoo lub zog siv tau raug txo kom ntau, kom lub peev xwm ntau lawm ntawm cov cuab yeej sib tsoo tuaj yeem ua tiav tag nrho, feem ntau lub pob zeb muaj peev xwm tuaj yeem nce los ntawm 20% ~ 50 %, thiab tag nrho cov kev siv hluav taws xob tuaj yeem raug txo los ntawm 30% ~ 50% lossis ntau dua.

Daim ntawv thov teb

Muaj ntau hom hlau ore hauv Suav teb, tab sis qhov zoo ntawm cov pob zeb hauv av feem ntau yog cov tsis zoo, lwm yam thiab zoo. Txhawm rau daws cov teeb meem zoo tshaj plaws hauv kev lag luam, kev lag luam thiab kev tiv thaiv ib puag ncig ntawm kev txhim kho mining, cov tuam txhab siv hlau hauv tsev ua haujlwm nquag qhia, zom thiab nqus cov khoom siv mining txawv teb chaws tshiab thiab muaj txiaj ntsig zoo. Hauv kev lag luam keeb kwm yav dhau los, HPGR yog cov cuab yeej sib tsoo ua tau zoo ua ntej tshawb fawb thiab ua qauv qhia, thiab pib siv rau hauv kev lag luam hlau hauv tsev. Nws tseem yog cov khoom siv mine ntau tshaj plaws los ntawm kev lag luam mining. Nws tuaj yeem hais tias HPGR tau siv dav hauv cov mines hlau hauv tsev. HPGR tau siv dav hauv tsev thiab txawv teb chaws hauv kev sib tsoo hauv kev lag luam cement, granulation hauv kev lag luam tshuaj, thiab kev sib tsoo zoo ntawm pellet kom nce qhov chaw tshwj xeeb. Nws yog siv rau kev sib tsoo ntawm cov hlau ore kom ua tiav cov hom phiaj sib txawv xws li kev ua kom yooj yim ntawm cov txheej txheem crushing, ntau crushing thiab tsawg sib tsoo, txhim kho cov khoom tsim tau, txhim kho cov nyhuv sib tsoo lossis cov ntsuas sib cais.

Tswv yim Scope

1. Nruab nrab, nplua thiab ultrafine sib tsoo ntawm cov ntaub ntawv loj.

2. Nyob rau hauv kev lag luam ntxhia, tuaj yeem muab tso ua ntej lub pob zeb, ua cov khoom sib tsoo ua ntej, los yog ua kom muaj kev sib xyaw ua ke nrog lub pob zeb.

3. Hauv kev lag luam oxidized pellet, tuaj yeem hloov cov khoom siv damp mills.

4.Hauv cov khoom siv hauv tsev, cov ntaub ntawv refractory thiab lwm yam lag luam, tau ua tiav hauv cov cement clinker, limestone, bauxite thiab lwm yam kev sib tsoo.

Khoom zoo

1. Kev tsim siab tas li ua kom lub siab du ntawm cov yob thiab ua kom cov nyhuv crushing.

2. Tsis siv neeg hloov pauv hloov kho, tuaj yeem kho qhov sib txawv ntawm qhov yob sai kom ntseeg tau tias cov khoom siv smoothness.

3. Kev sib cais ntawm ntug kev txo cov kev cuam tshuam ntawm ntug ntawm cov nyhuv crushing.

4. Nrog cemented carbide studs, lub neej ntev kev pab cuam, yooj yim txij nkawm, thiab hloov tau.

5. Lub txhab nyiaj valve txais cov khoom siv tuaj txawv teb chaws, thiab lub tshuab hydraulic muaj qhov tsim nyog thiab kev ntseeg tau zoo.

Qauv ntawm HPGR

| Qauv | Roll txoj kab uas hlamm | Roll dav mm | Tshaj tawmmuaj peev xwm | Pub loj | Tshuab hnyavt | Nruab lub zog |

| HWM 0630 | 600 | 300 | 25-40 | 10-30 | 6 | 74 |

| HWM 0850 | 800 | 500 | 50-110 : kuv | 20-35 | 25 | 150-220 : kuv |

| HPGM1050 | 1000 | 500 | 90-200 Nws | 20-35 | 52 | 260-400 Nws |

| HPGM1250 | 1200 | 500 | 170-300 Nws | 20-35 | 75 | 500-640 Nws |

| HWM 1260 | 1200 | 600 | 200-400 | 20-35 | 78 | 600-800 |

| HWM 1450 | 1400 | 500 | 200-400 | 30-40 | 168 | 600-800 |

| HWM 1480 | 1400 | 800 | 270-630 : kuv | 30-40 | 172 | 800-1260 : kuv |

| HWM 16100 | 1600 | 1000 | 470-1000 Nws | 30-50 | 220 | 1400-2000 Nws |

| HPGM16120 | 1600 | 1200 | 570-1120 : kuv | 30-50 | 230 | 1600-2240 Nws |

| HWM 16140 | 1600 | 1400 | 700-1250 Nws | 30-50 | 240 | 2000-2500 |

| HPGM18100 | 1800 | 1000 | 540-1120 : kuv | 30-60 | 225 | 1600-2240 Nws |

| HWM 18160 | 1800 | 1600 | 840-1600 Nws | 30-60 | 320 | 2500-3200 Nws |

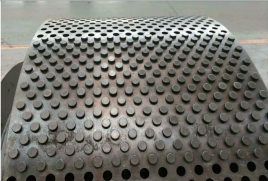

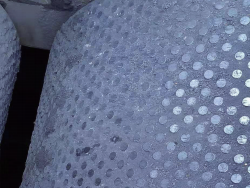

Tshiab hom stud yob nto tshuab

Nws txais cov khoom siv zoo zoo tawv tawv nrog cov tawv tawv thiab zoo hnav tsis kam.

Lub stud kev npaj yog tsim los ntawm computer simulation,

thiab kev npaj yog tsim nyog, uas tuaj yeem tsim cov khoom sib xws ntawm cov studs, zoo tiv thaiv cov studs thiab yob nto,

thiab txhim kho lub service lub neej ntawm squeezing yob . Cov studs tau nruab nrog cov nplaum tshwj xeeb uas tuaj yeem hloov tau yooj yim.

Sib cais tshuab ntawm yob bushing thiab lub ntsiab ncej

Lub cev tseem ceeb ntawm lub squeezing yob yog ua los ntawm high-zoo forged steel, thiab yob bushing yog forged nrog high-zoo alloy steel. Lub ntsiab ncej thiab cov yob yog ua los ntawm cov khoom sib txawv, uas txhim kho lub toughness ntawm lub ntsiab ncej thiab rigidity ntawm yob bushing. Kev pabcuam lub neej ntawm cov ncej bushing tau zoo heev. Kev hloov ntawm cov yob bushing yog yooj yim.

Bearing ceev mounting thiab dis-mounting tshuab High-quality tapered qhov bearings yog saws thiab high-siab roj tank yog preformed. Cov kabmob tuaj yeem yooj yim dismounted los ntawm cov roj twj tso kua mis siab, txo qhov nyuaj ntawm kev hloov cov kabmob thiab txhim kho kev txij nkawm.

Kev sib xyaw ua ke sealing tshuab

Cov kabmob foob tau txais ntau hom J-hom ntxiv rau V-hom thiab labyrinth seals, thiab cov cuab yeej sib txuas ua ke ua haujlwm tau zoo ua kom muaj kev sib khi ntawm cov kabmob.

Iron Ore Beneficiation Flow

High Quality Wear-Resistant Roll Surface nrog Studs

Tom qab cov khoom yog extruded,

txheej txheej txheej txheej yog tsim los ntawm yob nto los tiv thaiv yob nto.

Raw Khoom

Khoom qab zib