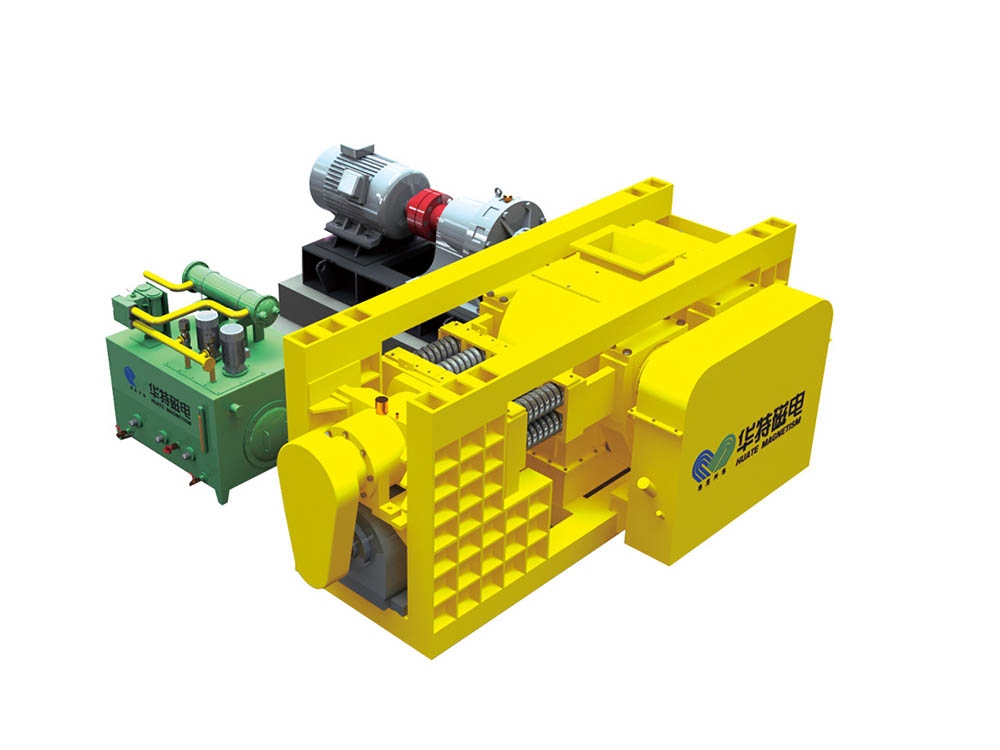

Series PGM Tib Tsav Siab Siab Cov Menyuam Mill

Daim Ntawv Thov Scope

Muaj ntau hom hlau ore hauv Suav teb, tab sis qhov zoo ntawm cov pob zeb hauv av feem ntau yog cov tsis zoo, lwm yam thiab zoo. Txhawm rau daws cov teeb meem zoo tshaj plaws hauv kev lag luam, kev lag luam thiab kev tiv thaiv ib puag ncig ntawm kev txhim kho mining, cov tuam txhab siv hlau hauv tsev ua haujlwm nquag qhia, zom thiab nqus cov khoom siv mining txawv teb chaws tshiab thiab muaj txiaj ntsig zoo. Hauv kev lag luam keeb kwm yav dhau los, HPGM yog cov cuab yeej ua haujlwm zoo sib tsoo thawj zaug tshawb fawb thiab ua qauv qhia, thiab pib siv rau hauv kev lag luam hlau hauv tsev. Nws tseem yog cov khoom siv mine ntau tshaj plaws los ntawm kev lag luam mining. Nws tuaj yeem hais tias HPGM tau siv dav hauv cov mines hlau hauv tsev. HPGM tau siv dav hauv tsev thiab txawv teb chaws hauv kev sib tsoo hauv kev lag luam cement, granulation hauv kev lag luam tshuaj, thiab kev sib tsoo zoo ntawm pellet kom nce qhov chaw tshwj xeeb. xws li simplifying cov txheej txheem crushing, ntau crushing thiab tsawg sib tsoo, txhim kho system productivity, txhim kho kev sib tsoo nyhuv los yog sib cais ntsuas.

Txoj Cai Ua Haujlwm

HPGM series siab sib tsoo yob yog ib yam tshiab ntawm lub zog txuag kev sib tsoo khoom tsim los ntawm lub hauv paus ntsiab lus ntawm high-pressure khoom txheej pulverization. Nws muaj ob lub squeezing yob uas tig synchronously ntawm ib tug tsawg ceev. Ib qho yog ib qho yob nyob ruaj ruaj thiab lwm qhov yog lub yob txav tau, uas yog ob qho tib si uas tau tsav los ntawm lub cev muaj zog. Cov ntaub ntawv yog sib npaug los ntawm saum toj no ob lub yob, thiab txuas ntxiv nqa mus rau hauv qhov sib txawv ntawm qhov sib tov los ntawm kev nyem yob. Tom qab raug kev kub ntxhov ntawm 50-300 MPa, lub ncuav mog qab zib tuab yog tawm ntawm lub tshuab. Nyob rau hauv lub ncuav mog qab zib cov khoom tawm, ntxiv rau ib qho kev faib ua feem ntawm cov khoom tsim nyog, cov qauv sab hauv ntawm cov khoom tsis tsim nyog tau ntim nrog ntau cov kab nrib pleb vim kev kub siab extrusion, yog li cov khoom muaj peev xwm zom tau. kho tau zoo heev. Rau cov ntaub ntawv tom qab extrusion, tom qab tawg, faib thiab tshuaj ntsuam, cov ntaub ntawv zoo ntawm tsawg dua 0.8 tuaj yeem ncav cuag li 30%, thiab cov ntaub ntawv tsawg dua 5 hli tuaj yeem ncav cuag ntau dua 80%. Yog li ntawd, nyob rau hauv cov txheej txheem sib tsoo ntxiv, kev sib tsoo lub zog siv tau raug txo kom ntau, kom lub peev xwm ntau lawm ntawm cov cuab yeej sib tsoo tuaj yeem ua tiav tag nrho, feem ntau lub pob zeb muaj peev xwm tuaj yeem nce los ntawm 20% ~ 50 %, thiab tag nrho cov kev siv hluav taws xob tuaj yeem raug txo los ntawm 30% ~ 50% lossis ntau dua.

Tswv yim Scope

1. Nruab nrab, nplua thiab ultrafine sib tsoo ntawm cov ntaub ntawv loj.

2. Nyob rau hauv kev lag luam ntxhia, tuaj yeem muab tso ua ntej lub pob zeb, ua cov khoom siv pregrinding, los yog ua kom sib xyaw ua ke nrog lub pob zeb.

3. Hauv kev lag luam oxidized pellet, tuaj yeem hloov cov khoom siv damp mills.

4.Hauv cov khoom siv hauv tsev, cov ntaub ntawv refractory thiab lwm yam lag luam, tau ua tiav hauv cov cement clinker, limestone, bauxite thiab lwm yam kev sib tsoo.

Product Advantages:

1. Kev tsim siab tas li ua kom lub siab du ntawm cov yob thiab ua kom cov nyhuv crushing.

2. Tsis siv neeg hloov pauv hloov kho, tuaj yeem kho qhov sib txawv ntawm qhov yob sai kom ntseeg tau tias cov khoom siv smoothness.

3. Kev sib cais ntawm ntug kev txo cov kev cuam tshuam ntawm ntug ntawm cov nyhuv crushing.

4. Nrog cemented carbide studs, lub neej ntev kev pab cuam, yooj yim txij nkawm, thiab hloov tau.

5. Lub txhab nyiaj valve txais cov khoom siv tuaj txawv teb chaws, thiab lub tshuab hydraulic muaj qhov tsim nyog thiab kev ntseeg tau zoo.

5. th

Khoom parameters

| Qauv | Roll txoj kab uas hla mm | Roll dav mm | Tshaj tawm muaj peev xwm | Pub loj | Tshuab hnyav t | Nruab lub zog | |

| HWM 0630 | 600 | 300 | 25-40 | 10-30 | 6 | 74 | |

| HWM 0850 | 800 | 500 | 50-110 : kuv | 20-35 | 25 | 150-220 : kuv | |

| HPGM1050 | 1000 | 500 | 90-200 Nws | 20-35 | 52 | 260-400 Nws | |

| HPGM1250 | 1200 | 500 | 170-300 Nws | 20-35 | 75 | 500-640 Nws | |

| HWM 1260 | 1200 | 600 | 200-400 | 20-35 | 78 | 600-800 | |

| HWM 1450 | 1400 | 500 | 200-400 | 30-40 | 168 | 600-800 | |

| HWM 1480 | 1400 | 800 | 270-630 : kuv | 30-40 | 172 | 800-1260 : kuv | |

| HWM 16100 | 1600 | 1000 | 470-1000 Nws | 30-50 | 220 | 1400-2000 Nws | |

| HPGM16120 | 1600 | 1200 | 570-1120 : kuv | 30-50 | 230 | 1600-2240 Nws | |

| HWM 16140 | 1600 | 1400 | 700-1250 Nws | 30-50 | 240 | 2000-2500 | |

| HPGM18100 | 1800 | 1000 | 540-1120 : kuv | 30-60 | 225 | 1600-2240 Nws | |

| HWM 18160 | 1800 | 1600 | 840-1600 Nws | 30-60 | 320 | 2500-3200 Nws | |

| rau siv xwb | |||||||

| [08] | |||||||

Technical nta:

Tshiab hom stud yob nto tshuab

Nws txais cov khoom siv zoo zoo tawv tawv nrog cov tawv tawv thiab zoo hnav tsis kam. Lub stud kev npaj yog tsim los ntawm lub computer simulation, thiab qhov kev npaj yog tsim nyog, uas muaj peev xwm tsim ib tug niaj hnub khoom txheej ntawm cov studs, zoo tiv thaiv cov studs thiab yob nto, thiab txhim kho lub neej kev pab cuam ntawm squeezing yob. Cov studs tau nruab nrog cov nplaum tshwj xeeb uas tuaj yeem hloov tau yooj yim.

Kev sib cais tshuab ntawm yob bushing thiab lub ntsiab ncej

Lub cev tseem ceeb ntawm lub squeezing yob yog ua los ntawm high-zoo forged steel, thiab yob bushing yog forged nrog high-zoo alloy steel. Lub ntsiab ncej thiab cov yob yog ua los ntawm cov khoom sib txawv, uas txhim kho lub toughness ntawm lub ntsiab ncej thiab rigidity ntawm yob bushing. Kev pabcuam lub neej ntawm cov ncej bushing tau zoo heev. Kev hloov ntawm cov yob bushing yog yooj yim.

Bearing ceev mounting thiab dismounting technology

High-quality tapered qhov bearings yog saws thiab siab siab roj tank yog preformed. Cov kabmob tuaj yeem yooj yim dismounted los ntawm cov roj twj tso kua mis siab, txo qhov nyuaj ntawm kev hloov cov kabmob thiab txhim kho kev txij nkawm.

Bearing ceev mounting thiab dismounting technology

High-quality tapered qhov bearings yog saws thiab siab siab roj tank yog preformed. Cov kabmob tuaj yeem yooj yim dismounted los ntawm cov roj twj tso kua mis siab, txo qhov nyuaj ntawm kev hloov cov kabmob thiab txhim kho kev txij nkawm.

Kev sib xyaw ua ke sealing tshuab

Cov kabmob foob tau txais ntau hom J-hom ntxiv rau V-hom thiab labyrinth seals, thiab cov cuab yeej sib txuas ua ke ua haujlwm tau zoo ua kom muaj kev sib khi ntawm cov kabmob.

Siab zog ncej

Cov ncej yog welded nrog high-zoo carbon structural steel. Tag nrho cov ncej lub zog yog kuaj peb-dimensionally, nrog lub zog siab thiab kev ntseeg tau zoo. Lub thav duab yog ua tiav los ntawm ib qho annealing thiab cov ncej deformation yog me me.

High quality thiab txhim khu kev qha hy-draulic system

Raws li cov yam ntxwv crushing ntawm cov khoom sib txawv, lub siab tsis zoo ntawm hydraulic system yog optimized, thiab ib tug tshwj xeeb tsim yog saws tshwj xeeb tshaj yog rau cov crushing yam ntxwv ntawm hlau minerals xws li hlau ore thiab manganese ore. Cov pab pawg hydraulic valve txais yuav cov khoom lag luam nrov npe nrov thiab muaj kev ntseeg siab thiab ruaj khov.

Automated tswj system thiab centralized lubrication system

Nrog Siemens PLC thiab lub vijtsam kov tag nrho, thiab cov txheej txheem tswj hwm tag nrho, tag nrho lub tshuab tuaj yeem ua tsis tau, thiab lub siab thiab ntau yam tsis tuaj yeem hloov kho tau yooj yim los pab txhawb kev sib tsoo ntawm cov ntxhia sib txawv. Tag nrho lub tshuab txais lub hauv paus system lubrication, uas tuaj yeem kho tus nqi lubrication thiab zaus nrog kev ua haujlwm.

Daim ntawv thov Site