QHOV TSEEB

Technical nta

1).Qhov siab tshaj plaws sib nqus: 20000GS.

2).Kev txuag dej tsawg kawg yog 8000 cubic meter ib xyoos twg.

3).Extherm tuaj yeem tswj tau nrog 30 ℃.

4).Roj-txias system los hloov cov qub-fashion dej-txias.

5).Compact qauv, yooj yim rau nruab thiab khiav lag luam.

6).Cov coil zoo siab tau dipped rau hauv cov roj transformer kom ntev lub sijhawm ua haujlwm.

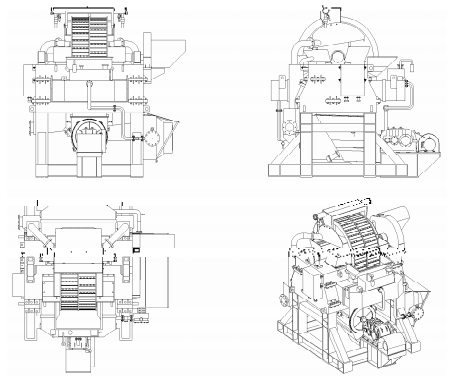

Qauv

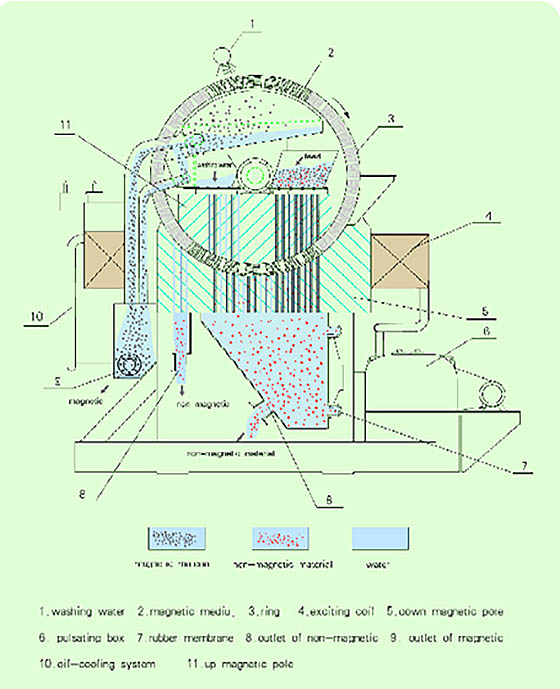

Cov txheej txheem sib cais

Patenttechnical innovation point 1

Coils

Kev tsim tshwj xeeb ntawm cov coil zoo siab, muaj qhov khoob ntawm cov winding coils uas muab cov roj cua txias.Ua kom thaj chaw tawg thiab cov roj-txias cov kav dej.Kev sib hloov ceev ceev.Chev kub nce tsis tshaj 30 ℃, tsis tshua muaj kub nce nyob rau hauv txias thiab kub lub xeev, magnetic teb sib txawv me me, piv nrog tib lub sib nqus teb zog, lub excitation zog txo 20%, txuag hluav taws xob 45000 KWh / xyoo.

Cov qauv kaw tag nrho, pov thawj plua plav, pov thawj noo noo, kub resistant, nws tuaj yeem ua haujlwm hauv ib puag ncig hnyav.

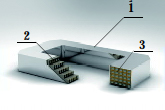

Coil qauv thiab lub hauv paus ntsiab lus cua txias sib piv daim duab

lwm cov tuam txhab (thawj tiam) hauv hollow conductors dej txias

1. coil vaj tse 2. dej txias 3. hollow conductorlwm cov tuam txhab (thib ob) ntawm cov coils dej txias

1. coil vaj tse 2. dej txias 3. multilayers coils muaj dej puv 4. lub tes tsho dej (stainless steel)

Shandong Huate (thib peb tiam) roj txias coils yog dipped hauv roj

1. coil tsev 2. roj dhau (cov roj txias) 3. ib txheej winding roj

Patent technical innovation point 2

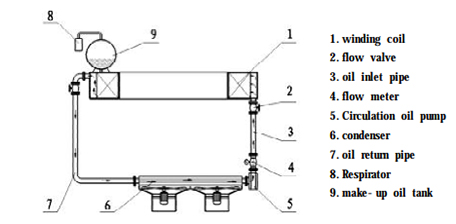

Txias qhov system

1. Lub tshuab ua kom txias tau txais cov txheej txheem ntim cov txheej txheem tag nrho, los nag-pov thawj, pov thawj plua plav, tiv thaiv corrosion, haum rau txhua yam hnyav ib puag ncig.

2. Txais cua txias condenser, ntse tswj, excitation coil kub yog tas li, magnetic teb fluctuation yam tsawg kawg nkaus (tsawg dua 2%) ntawm txias hom, lwm yam domestic manufacturers ua coil kub siab dhau lawm, magnetic teb fluctuation ncav cuag 15% ~ 30%, uas muaj kev cuam tshuam zoo rau ore hnav khaub ncaws indexes.

3. Nrog loj ntws disc transformer roj twj tso kua mis, khiav ceev ceev, ceev pauv kub.

Daim duab cua txias system

Forced roj txias system muaj xws li winding coil, roj-inlet raj, xa rov qab kab, condenser, roj ncig twj tso kua mis, flow meter, flow valve, thermocouple, make-up roj tank, respirator, thiab lwm yam.

Kev xaiv txoj kev: feem ntau peb xaiv cov khoom siv raws li lub peev xwm ntawm concentrator.

Nco tseg:cov ntaub ntawv liab txhais tau hais tias meduim siv siab gradient sib nqus sib cais.

(Rau siv xwb)

Qhov chaw